So I am in the design stage of putting together a compost tea brewer. I have a bit of experience brewing compost/worm tea, but nothing on this scale. I know that most everyone uses large air pumps for gas diffusion, but I have a different idea. I am hoping some of you that brew AACT a lot can give me a sanity check.

Here are the requirements for the brewer:

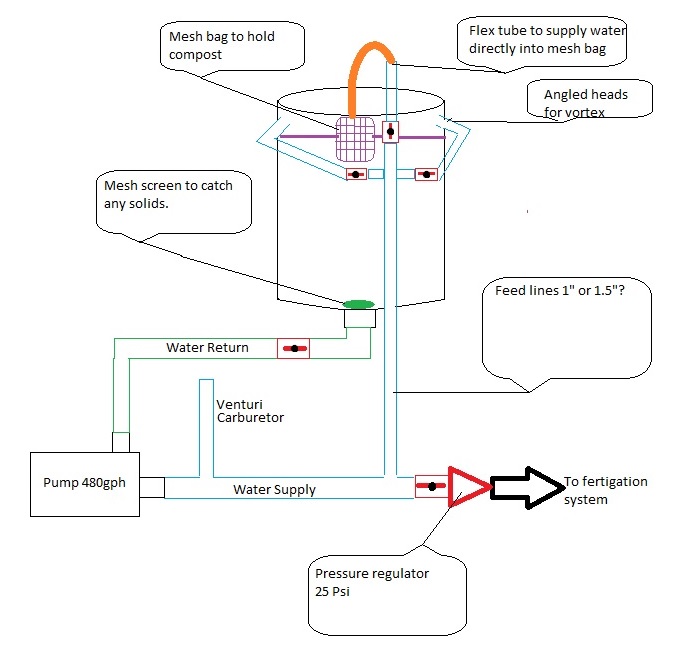

Here is a diagram of what I am thinking

Now, I know the first thing that everyone is going to jump all over is the lack of an air pump. The way I figure, I have to put a water pump into the mix to accomplish requirement #3, so with venturi carburetor, the vortex, and breaking the surface tension, I think I will be able to get the gas diffusion I need. I am open to arguments on this, but if I have to buy a $100 air pump AND a $100 water pump, that might blow requirement #2.

I plan to hang the tea bag from a piece of 3/8" threaded rod running through the top of the bucket. The pump I am looking at should be able to handle a small amount of solids, but nothing larger than coarse sand.

Like I said, this is all in the design stage right now, so if anyone has thoughts, I would love to hear them before I start working on the construction.

Here are the requirements for the brewer:

- Needs to be overkill - 5 gallon buckets are not enough, but I probably wont go through 40-50 gallons either

- Needs to be cheap - I realize I can buy a kit for around $600, so I need to be way under that number

- Final product needs to be pumped directly out to the garden - I don't want to fill a backpack sprayer 10 times, or carry buckets around, plus since I already have irrigation, makes sense to just pump it straight into the system. (Maybe figure out a way to dilute in the process?)

Here is a diagram of what I am thinking

Now, I know the first thing that everyone is going to jump all over is the lack of an air pump. The way I figure, I have to put a water pump into the mix to accomplish requirement #3, so with venturi carburetor, the vortex, and breaking the surface tension, I think I will be able to get the gas diffusion I need. I am open to arguments on this, but if I have to buy a $100 air pump AND a $100 water pump, that might blow requirement #2.

I plan to hang the tea bag from a piece of 3/8" threaded rod running through the top of the bucket. The pump I am looking at should be able to handle a small amount of solids, but nothing larger than coarse sand.

Like I said, this is all in the design stage right now, so if anyone has thoughts, I would love to hear them before I start working on the construction.