-

Do you need help identifying a 🌶️?

Is your plant suffering from an unknown issue? 🤧

Then ask in Identification and Diagnosis. -

✅ Expert and friendly hot pepper grow advice.

✅ The latest information on hot pepper varieties.

✅ Reliable seed trading.

✅ Hot sauce recipes and food safety guidance.

✅ Hot sauce business tips for startups.

🌶️ And more!

It's all here, at The Hot Pepper! The Internet's original hot pepper community! Est. 2004.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HOW TO BUILD AN LED GROWLIGHT

- Thread starter N8thaniel

- Start date

Hey,

So trying to wrap my head around LED's and the drivers required.

Do they work the same as everything else? for example;

If the LED has the forward voltage of 31.3V And the max current of 1.05A and I wanted to have 6 of them.

Does that mean that each COB is 32.8W? so I would need a 190V power supply with at least 19A current?

Unless there is a special rule for LED's, isnt this the general rule to figure out power requirements?

So trying to wrap my head around LED's and the drivers required.

Do they work the same as everything else? for example;

If the LED has the forward voltage of 31.3V And the max current of 1.05A and I wanted to have 6 of them.

Does that mean that each COB is 32.8W? so I would need a 190V power supply with at least 19A current?

Unless there is a special rule for LED's, isnt this the general rule to figure out power requirements?

LocalFart said:Hold on.

I think I figured out where im going wrong...

I was thinking I need 19A @ 31.3V but ramping up to 190V i will only need 1A?

I hope thats right...

Its not... I'll let the local expert reply here.

LocalFart said:Hey,

So trying to wrap my head around LED's and the drivers required.

Do they work the same as everything else? for example;

If the LED has the forward voltage of 31.3V And the max current of 1.05A and I wanted to have 6 of them.

Does that mean that each COB is 32.8W? so I would need a 190V power supply with at least 19A current?

Unless there is a special rule for LED's, isnt this the general rule to figure out power requirements?

forward voltage of LED chip is about 1.8V - 3.3V

a little bit increase in voltage will create tremendous increase in current. You don't wanna burn your LED ,right? You have to focus more on constant current driver.

you need to understand simple serial / parallel circuit then you can drive your LED at maximum power without burning it.

Okay, turns out I have been looking at some pretty overpowered LED's when doing my initial search, I was able to wrap my head around it a bit better after posting on here.

Product Overview

Digi-Key Part Number

CXA1507-0000-000N00G265F-ND

Quantity Available

75

Can ship immediately

Manufacturer

Cree Inc.

Manufacturer Part Number

CXA1507-0000-000N00G265F

Description

LED ARRAY XLAMP CXA1507 WHITE

Expanded Description

LED Lighting COBs, Engines, Modules Chip On Board (COB) XLamp® CXA1507 White, Cool Square

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Moisture Sensitivity Level (MSL)

1 (Unlimited)

Manufacturer Standard Lead Time

4 Weeks

Documents & Media

Datasheets

CXA1507 Series

Design Resources

Development Tool Selector

Lighting Product Selector

Featured Product

CXA LED Array – Cree

Online Catalog

XLamp® CXA1507 LEDs

Product Attributes

Select All

Categories

Optoelectronics

LED Lighting - COBs, Engines, Modules

Manufacturer

Cree Inc.

Series

XLamp® CXA1507

Packaging

Tray

Part Status

Active

Type

Chip On Board (COB)

Color

White, Cool

CCT (K)

6500K 4-Step MacAdam Ellipse

Wavelength

-

Configuration

Square

Flux @ Current/Temperature - Test

810 lm (780 lm ~ 840 lm)

Current - Test

200mA

Temperature - Test

85°C

Voltage - Forward (Vf) (Typ)

37V

Lumens/Watt @ Current - Test

110 lm/W

Current - Max

375mA

CRI (Color Rendering Index)

70

Viewing Angle

115°

Features

-

Size / Dimension

15.85mm L x 15.85mm W

Height

1.70mm

Light Emitting Surface (LES)

8.90mm Diameter

Lens Type

Flat

So I guess I am asking for a little help understanding. So if possible can you help me understand 'simple serial / parallel circuits'?

Product Overview

Digi-Key Part Number

CXA1507-0000-000N00G265F-ND

Quantity Available

75

Can ship immediately

Manufacturer

Cree Inc.

Manufacturer Part Number

CXA1507-0000-000N00G265F

Description

LED ARRAY XLAMP CXA1507 WHITE

Expanded Description

LED Lighting COBs, Engines, Modules Chip On Board (COB) XLamp® CXA1507 White, Cool Square

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Moisture Sensitivity Level (MSL)

1 (Unlimited)

Manufacturer Standard Lead Time

4 Weeks

Documents & Media

Datasheets

CXA1507 Series

Design Resources

Development Tool Selector

Lighting Product Selector

Featured Product

CXA LED Array – Cree

Online Catalog

XLamp® CXA1507 LEDs

Product Attributes

Select All

Categories

Optoelectronics

LED Lighting - COBs, Engines, Modules

Manufacturer

Cree Inc.

Series

XLamp® CXA1507

Packaging

Tray

Part Status

Active

Type

Chip On Board (COB)

Color

White, Cool

CCT (K)

6500K 4-Step MacAdam Ellipse

Wavelength

-

Configuration

Square

Flux @ Current/Temperature - Test

810 lm (780 lm ~ 840 lm)

Current - Test

200mA

Temperature - Test

85°C

Voltage - Forward (Vf) (Typ)

37V

Lumens/Watt @ Current - Test

110 lm/W

Current - Max

375mA

CRI (Color Rendering Index)

70

Viewing Angle

115°

Features

-

Size / Dimension

15.85mm L x 15.85mm W

Height

1.70mm

Light Emitting Surface (LES)

8.90mm Diameter

Lens Type

Flat

So I guess I am asking for a little help understanding. So if possible can you help me understand 'simple serial / parallel circuits'?

Still planning to make some, on my long list.

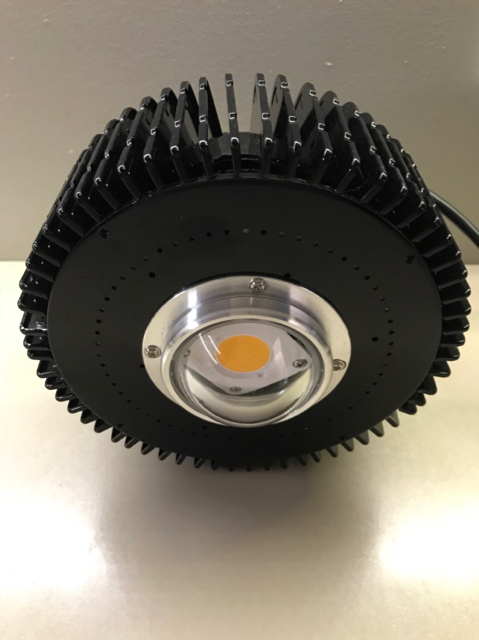

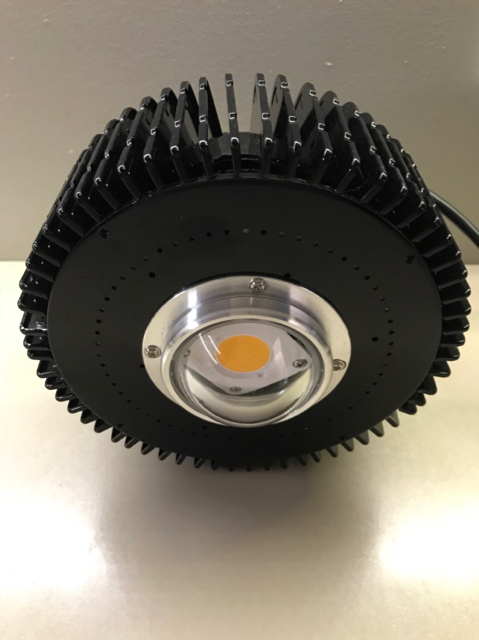

This looks really good! Would you mind sharing a few more details, e.g. power supply used, heatsink needed, etc.? I think this might be absolutely perfect for starting grows indoors before moving plants out in the spring!KAOS said:Posted this in another thread, but put together for around $25US.

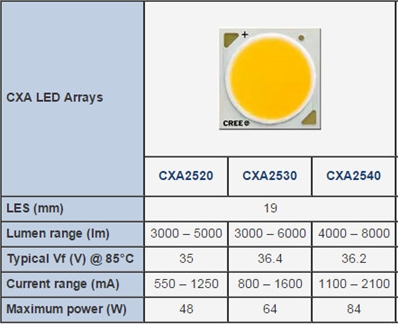

2 x CXA2520 @ 30W each

Sent from my iPhone using Tapatalk

Sent from my ZTE A2017G using Tapatalk

lespaulde said:This looks really good! Would you mind sharing a few more details, e.g. power supply used, heatsink needed, etc.? I think this might be absolutely perfect for starting grows indoors before moving plants out in the spring!

Sent from my ZTE A2017G using Tapatalk

I'll take some more pics and put some details up tomorrow.

Some more pics of LED test light.

This was assembled on an old aluminium plate probably 1.6mm thick and 310mm x 210mm in size

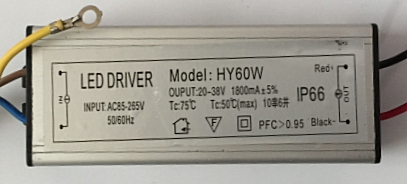

Power supply is 1500mA 20-39V. The chips are connected in parallel.

What is not shown is the cooling. Didnt get that far with a permanent solution yet so all I had was an old pc heatsink and fan with some thermal paste sitting loose. Let it run overnight and temps were less than 50C.

Next project on the list is two CXA2540s powered by two 60W drivers on a descent 300mm x 140mm x 20mm heatsink. Forced air via 120mm/140mm case fan. Will be a more polished build and estimating a power draw of 130-140W.

Did some measurements with a lightmeter and get around 6600lux at 50cm with the 2520s. I did a comparative check with a bought CLU048 unit ($105USD) which is 7700lux at 50cm. Photo of unit below. Not bad for two little LEDs.

Sent from my iPhone using Tapatalk

This was assembled on an old aluminium plate probably 1.6mm thick and 310mm x 210mm in size

Power supply is 1500mA 20-39V. The chips are connected in parallel.

What is not shown is the cooling. Didnt get that far with a permanent solution yet so all I had was an old pc heatsink and fan with some thermal paste sitting loose. Let it run overnight and temps were less than 50C.

Next project on the list is two CXA2540s powered by two 60W drivers on a descent 300mm x 140mm x 20mm heatsink. Forced air via 120mm/140mm case fan. Will be a more polished build and estimating a power draw of 130-140W.

Did some measurements with a lightmeter and get around 6600lux at 50cm with the 2520s. I did a comparative check with a bought CLU048 unit ($105USD) which is 7700lux at 50cm. Photo of unit below. Not bad for two little LEDs.

Sent from my iPhone using Tapatalk

Very cool, thanks for the details and for providing some clarity for those like me who are still wrapping their head around the details. I think it's very impressive indeed what can be done with LED technology these days and I'd love to jump on the train to get a better head start next season. So the 2540s are a heavier version of the 2520 if I interpret the spec sheet correctly? Which color temp would you recommend overall if one were to set up a double LED system, still closer to the blue-ish spectrum? And so the power supply just runs a constant voltage and current, and no need for adjustments? You almost make it seem too easy, awesomeness!

Many, many thanks again

Sent from my ZTE A2017G using Tapatalk

Many, many thanks again

Sent from my ZTE A2017G using Tapatalk

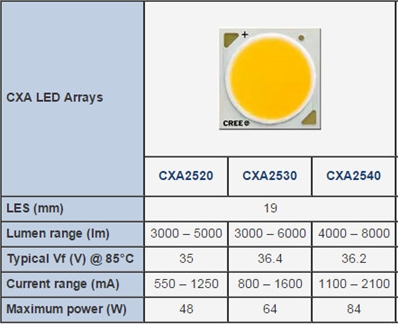

The 2540's are almost double the rating, but that being said the die (both the same size) will have to cope with equally as much heat dissipation, so better cooling required.

I still think the 2520's are best bang for buck and my setup above only drives them to 63% of their rating. Use a pair of the 2520's on a 60W driver and I'm sure they would out perform a 2540 (at a similar price point).

I was confused by power supplies also, but then simplified it in my mind. This is not 100%, but you shouldn't blow sh1t up if followed.

Step 1 - Choose a constant current driver

Step 2 - Make sure the operating voltage range covers your LED forward voltage (Vf)

Step 3 - Add LED's in parallel summing up their current usage.

Step 4 - Try keep their working power 60 - 80% of their max rating

The reason for operating at lower than max rating is simple - efficiency and heat.

Stolen from another website....

For your example CXB3590 CB 36V @ 700ma VS CXB3590 CB 36V @ 1.4A

if 700ma 22.9 watts @ 58.71% efficiency 22.9 x 58.71% = 13.45 par watts / 9.94 heat watts

if 1.4A 48.85 watts @ 51.67% efficiency 48.85 x 51.67% = 25.24 par watts / 23.61 heat watts

So if you run twice as many COB's at lower current you get more PAR watts compared to running less COB's at higher current.

4 @ 700ma = 91.6 watts / 53.8 par / 39.76 heat

2 @ 1.4A = 97.7 watts / 50.48 par / 47.22 heat

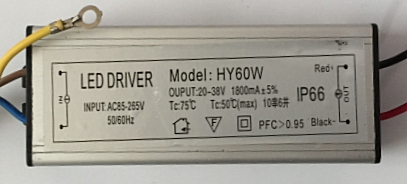

Example 1

- I have two 2520's (Vforward is 35V / Max power is 48W). I have two of these so max power is 96W

- I want to drive this to 60% of the rated 96W = 57W

- Typically drivers have a +- 5% tolerance so I choose a 50W driver for worst case (50W + 5% = 53W). Pretty close to the 57W I was aiming for.

- Check the driver's voltage range (35V - chosen one is 20-39V) so this will work.

- In this case I could have upped to a 60W driver and driven it to 71% of chip rating (I chose not to as 50W driver $12NZD and 60W driver $20NZD)

Example 2

- I have one 2540 (Vforward is 36.2V / Max power is 84W)

- I want to drive this to 80% of the rated 84W = 67W

- Typically drivers have a +- 5% tolerance so I choose a 60W driver for worst case (60W + 5% = 63W). Pretty close to the 67W I was aiming for.

- Check the driver's voltage range (36.2V - chosen one is 20-38V) so this will work.

All this being said though the 50W driver I bought (being a generic) has a tolerance of +20% so the safety factors above play in well.

I will be testing the 2520's on the 60W driver when it arrives so will have an update in a week or two.

Example 3

- I have three 500mm rigid strips of 5630smd that are rated at 12Vforward and 13W typical. I have tested these to 25W max (but then they get real hot real quick)

- I have a 50W driver with working voltage of 20-39V.

- I assume worst cast tolerance to 53W and divide by 3 (53 / 3 = 17.6W per strip)

- This is over it's typical, but under the tested max so should be ok.

- I connect them in series so add their Vforward together (12V + 12V + 12V = 36V). This is within the driver operating voltage so should work.

I have however played with the cheap 12V power supplies where you can change the output voltage from 11V - 14V and these are far cheaper than dedicated drivers to power rigid strips. They unfortunately are not constant current drivers though.

I still think the 2520's are best bang for buck and my setup above only drives them to 63% of their rating. Use a pair of the 2520's on a 60W driver and I'm sure they would out perform a 2540 (at a similar price point).

I was confused by power supplies also, but then simplified it in my mind. This is not 100%, but you shouldn't blow sh1t up if followed.

Step 1 - Choose a constant current driver

Step 2 - Make sure the operating voltage range covers your LED forward voltage (Vf)

Step 3 - Add LED's in parallel summing up their current usage.

Step 4 - Try keep their working power 60 - 80% of their max rating

The reason for operating at lower than max rating is simple - efficiency and heat.

Stolen from another website....

For your example CXB3590 CB 36V @ 700ma VS CXB3590 CB 36V @ 1.4A

if 700ma 22.9 watts @ 58.71% efficiency 22.9 x 58.71% = 13.45 par watts / 9.94 heat watts

if 1.4A 48.85 watts @ 51.67% efficiency 48.85 x 51.67% = 25.24 par watts / 23.61 heat watts

So if you run twice as many COB's at lower current you get more PAR watts compared to running less COB's at higher current.

4 @ 700ma = 91.6 watts / 53.8 par / 39.76 heat

2 @ 1.4A = 97.7 watts / 50.48 par / 47.22 heat

Example 1

- I have two 2520's (Vforward is 35V / Max power is 48W). I have two of these so max power is 96W

- I want to drive this to 60% of the rated 96W = 57W

- Typically drivers have a +- 5% tolerance so I choose a 50W driver for worst case (50W + 5% = 53W). Pretty close to the 57W I was aiming for.

- Check the driver's voltage range (35V - chosen one is 20-39V) so this will work.

- In this case I could have upped to a 60W driver and driven it to 71% of chip rating (I chose not to as 50W driver $12NZD and 60W driver $20NZD)

Example 2

- I have one 2540 (Vforward is 36.2V / Max power is 84W)

- I want to drive this to 80% of the rated 84W = 67W

- Typically drivers have a +- 5% tolerance so I choose a 60W driver for worst case (60W + 5% = 63W). Pretty close to the 67W I was aiming for.

- Check the driver's voltage range (36.2V - chosen one is 20-38V) so this will work.

All this being said though the 50W driver I bought (being a generic) has a tolerance of +20% so the safety factors above play in well.

I will be testing the 2520's on the 60W driver when it arrives so will have an update in a week or two.

Example 3

- I have three 500mm rigid strips of 5630smd that are rated at 12Vforward and 13W typical. I have tested these to 25W max (but then they get real hot real quick)

- I have a 50W driver with working voltage of 20-39V.

- I assume worst cast tolerance to 53W and divide by 3 (53 / 3 = 17.6W per strip)

- This is over it's typical, but under the tested max so should be ok.

- I connect them in series so add their Vforward together (12V + 12V + 12V = 36V). This is within the driver operating voltage so should work.

I have however played with the cheap 12V power supplies where you can change the output voltage from 11V - 14V and these are far cheaper than dedicated drivers to power rigid strips. They unfortunately are not constant current drivers though.

lespaulde said:Which color temp would you recommend overall if one were to set up a double LED system, still closer to the blue-ish spectrum?

Forgot to answer this ↑

Peeps will chime in here i guess and yes it's true to say blueish is best for growth, but I've watched enough youtube light comparisons (blue vs red) and played with many different units to come to my own conclusion.

The secret is neither red nor blue, but green ...

There is a reason plants grow best in sunlight and yes blue is for veg / red is for flowering, but I forget the science around green. It has something to do with signalling.

My colour of choice, long story short, is 4000k or as close to that as possible.

Hi Poiethis. Just playing around at this stage so cant comment on suitability for chillies. I have no doubt that they will work nicely though and have ordered some gear for a 2540 build. Ideally I need 120W (high lm/W) or more (lower lm/W) in the tent to look after the plants so hopefully I can get there with the new chips. I would need a 4 x 2520 build to achieve this and may still do that to have an emergency spare unit.Poiethis said:I was looking at the 2520s too for a nice balance between cost and power. How's the setup working for you?

My go to light however is a full spectrum white with 5 x 300W COBs. It draws 230W from the socket and is not terribly efficient but has a magical light spectrum. Did some searching and it uses COBs designed for projectors. Plants seem to love it and the inefficiency plays in well during winter as it provides enough heat to keep the cold off the plants.

Cobbled this together using 5630 rigid strips and aluminium end pieces from partitioning.

Still need to properly mount a fan and the psu. In the photo it’s running at 60W and producing 4800lux at 50cm. Build is good up to 120w and 7700lux so comparable to light intensity of the bought unit.

Total cost around $23USD excluding the fan.

The idea behind this was to build a 4 bank array of around 240w that could be switched in and out one at a time to simulate sunrise and sunset.

Sent from my iPhone using Tapatalk

Still need to properly mount a fan and the psu. In the photo it’s running at 60W and producing 4800lux at 50cm. Build is good up to 120w and 7700lux so comparable to light intensity of the bought unit.

Total cost around $23USD excluding the fan.

The idea behind this was to build a 4 bank array of around 240w that could be switched in and out one at a time to simulate sunrise and sunset.

Sent from my iPhone using Tapatalk

Looks SO awesome!

Sent from my ZTE A2017G using TapatalkKAOS said:Got the 5630 panel up and running in the tent now. She does run a bit warm at rated voltage, so under-driving it a bit.