The_NorthEast_ChileMan said:Yes but you've done this more than anyone I know of and you have all that knowledge & experience stored in that memory stick between your ears! Two things though........... #1 is his location:

And #2 is his description of "commercial" canning. I'm still trying to figure out the size he's talking about but I believe it's way beyond a household kitchen or any co-packer you're used to. Knowing you as I do, I figure we'll be able to muddle through!

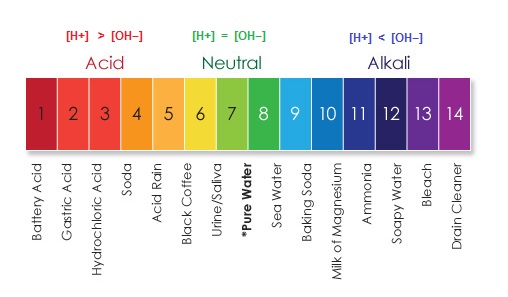

So now that I've buttered you up............. OP has a pH meter and I know pH is 3 something or other, correct?

As for #1, the only major thing is see is regulations difference. Otherwise I can source all the materials / equipment required for this project.

#2 Probably start with a few metric tons and then scale from there. I will not start with fancy equipment from the get go, however at the same time I do not want to skimp on any of the safety protocols. I can get a vacuum sealer machine, but that will only work for glass jars and not for tins or plastic jars. I'm basically going to be targeting two markets: Retail (home user) and Bulk (institutional packing for restaurants, hotels etc). I will probably go with glass jars for retail sale but am still undecided on how to proceed with bulk sale packaging. At the same time I'm even considering using plastic for all if it can be UV sterilized, because that will result in the crunchiest possible product.