After hearing about the Vevor recommended in another thread. I bought direct from the Mfg, they were a couple hundred cheaper than other online sellers.

m.vevor.com

m.vevor.com

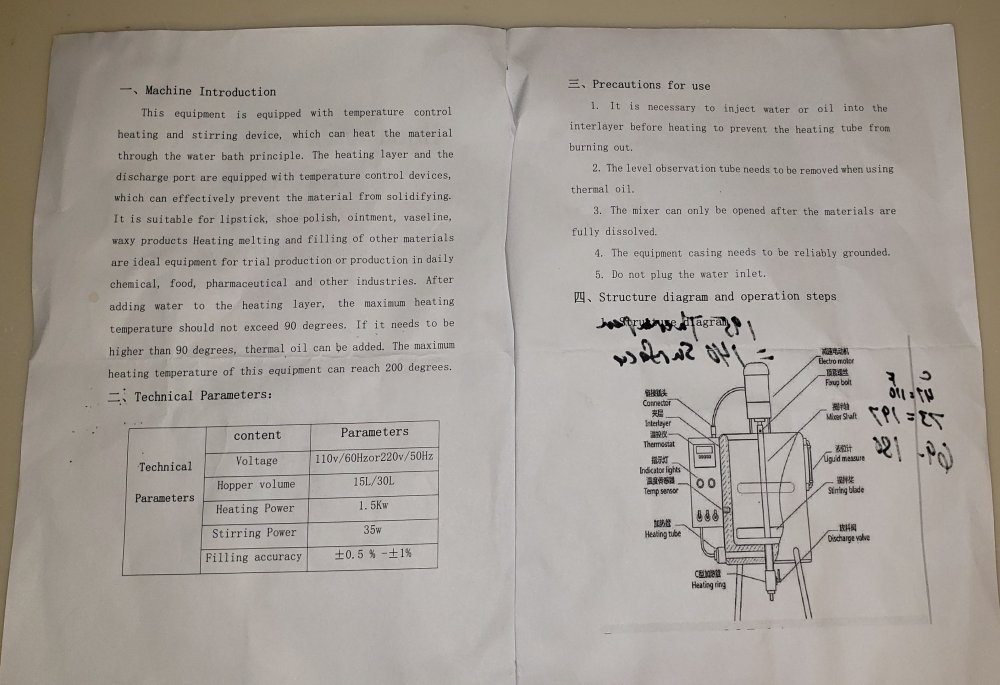

It is a stainless steel jacketed kettle, heat adjustable, ball valve dispenser with a stirring paddle with a pretty heavy motor. Here is the very comprehensive owners manual.

The barb that came with it was the smallest one on the left. I hit up the local hardware store for 2 larger fitting,. The middle one fits into woozies and the larger one will work for quadra bottles and 12 oz sauce bottles.

The motor connector is close to the vat and at risk of getting splashed with water, soap, and or sauce. I pulled a couple plugs from an electrical insulated splice boot, it fit perfectly to cover the connector while cleaning the vat. The controls had no indication on the unit or in the instructions as to what did what. Pics in next post.

The top of the barb was too close to the table to fit 10 oz woozy or sauce bottles. Stuck everything on a couple hotel pans, that was workable. I also had to rig up a funnel since the half lid wouldn't stay open and it was kind of a small opening to try to pour into.

Now the really fun stuff....

The vat is advertised as 15L. This should fit...

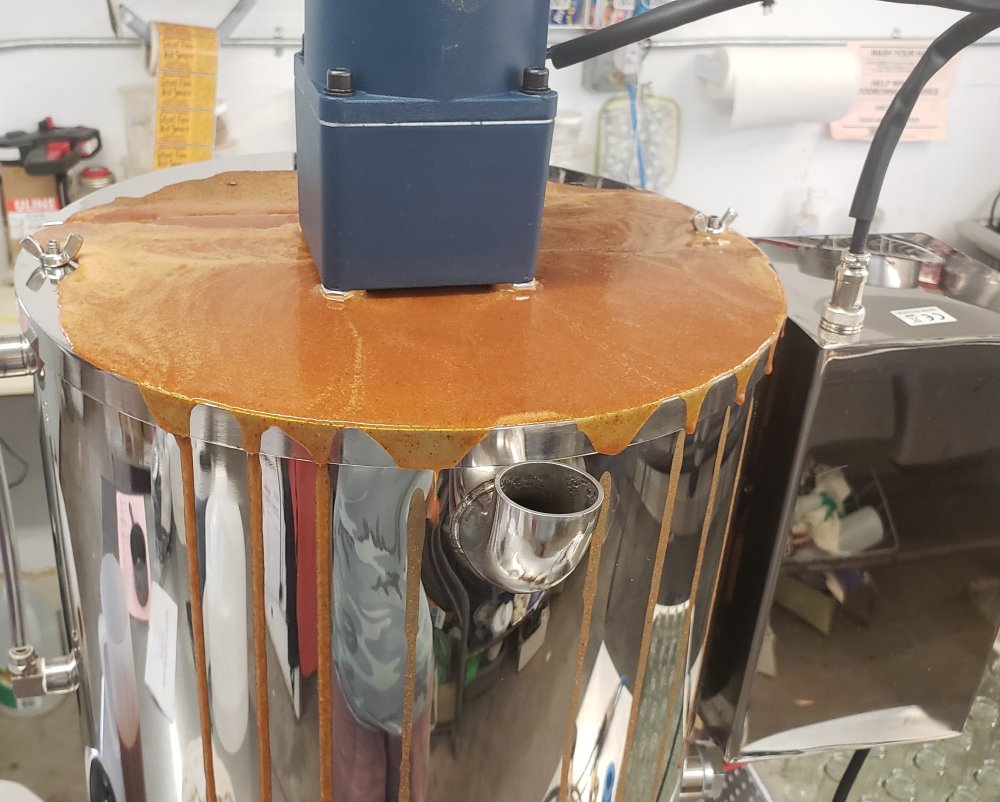

Except....when heated, sauce expands, and when it boils, it does this...

there is a gap between the motor housing and the lid, so the motor wasn't in danger, just a big mess. The large L pipe is where the water (or oil) goes into the outer jacket. you can see the motor connection point on the right.

The digital heat controller was waaay off. When using the valve heatern around the ball valve, the sauce was coming out boiling resulting in very short filled bottles. Using the Thermapen, the sauce was around 205F while the digital read out was saying 80C. 205F=96C, display read 80C. Waaaay off. For the next batch, I compensated. It will take a few batches to get it dialed in.

Learning curve was pretty steep. Next batch was Tropical Ghost Sauce which has bits of carrot. The bits are pretty small, but enough to get stuck in the barb every 3rd or 4th bottle. Stop, put a bowl under it, use a wire to unclog it, Big Mess!!! Sometimes the sauce would stop up, then splooge out, overfilling the bottles making a big mess on each bottle that then had to be wiped clean on the threads before capping.

Inside of the fitting at cleaning

Another note is, the whole thing is so high sitting on the table and hotel pans, I had to get a stepstool to be able to clean it. When finished with a batch, the jacket is still VERY hot. I was wanting to save the distilled water in the jacket for the next batch, so I didn't want to drain the water just to clean it. It took over 2 1/2 gallons of distilled water for the jacket.

I ended up filling the kettle with cold soapy water, which chilled the jacket enough to warm water to clean it soon after finished with filling.

And then had to drain the soapy water into a half gallon scoop and dump into a 5 gallon bin.

Good points...It is Heated! For the Tropical batch, the batch was large enough that I put half in the hopper and half on the stove. Both seemed to heat up at the same rate. Benefit of the Adgie...(agitator) was that I didnt have to babysit it stirring it like I did with the pot on the stove.

The ball valve was pretty good on the GhostFire, which is pretty homogenous. Accurate stopping. It did kind of have a little latent drip between bottles. I ended up not using the measuring cup prop. Just held them by hand. It did not go so well with the Tropical with the carrot bits.

The agitator was a great feature during processing, and the heating feature will be good once I get the read out correlated to the actual sauce temp.

2 thicker sauces coming up this weekend. BBQ and the new Spicy Catsup. Those will be using the larger barb. We'll see....

VEVOR Heating Mixing Filling Machine, 15L/4 Gal Lipstick Filling Machine, 35W Lipstick Filler, Heating and Stirring Filling Machine with Stirrer for Cosmetics, Drink, Lipstick, Wax and Nail Polish | VEVOR US

VEVOR Lipstick Filling Machine revolutionizes cosmetics production. Thermostat heating, striking working power, smart operating system, 15L volume hopper, and durable SUS structure.

It is a stainless steel jacketed kettle, heat adjustable, ball valve dispenser with a stirring paddle with a pretty heavy motor. Here is the very comprehensive owners manual.

The barb that came with it was the smallest one on the left. I hit up the local hardware store for 2 larger fitting,. The middle one fits into woozies and the larger one will work for quadra bottles and 12 oz sauce bottles.

The motor connector is close to the vat and at risk of getting splashed with water, soap, and or sauce. I pulled a couple plugs from an electrical insulated splice boot, it fit perfectly to cover the connector while cleaning the vat. The controls had no indication on the unit or in the instructions as to what did what. Pics in next post.

The top of the barb was too close to the table to fit 10 oz woozy or sauce bottles. Stuck everything on a couple hotel pans, that was workable. I also had to rig up a funnel since the half lid wouldn't stay open and it was kind of a small opening to try to pour into.

Now the really fun stuff....

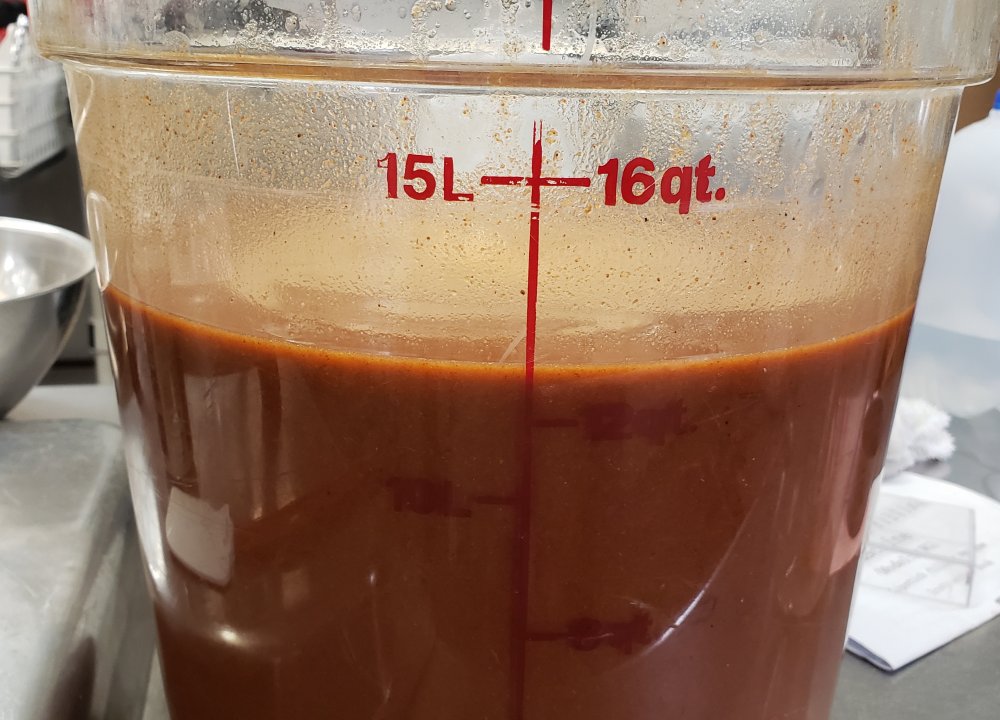

The vat is advertised as 15L. This should fit...

Except....when heated, sauce expands, and when it boils, it does this...

there is a gap between the motor housing and the lid, so the motor wasn't in danger, just a big mess. The large L pipe is where the water (or oil) goes into the outer jacket. you can see the motor connection point on the right.

The digital heat controller was waaay off. When using the valve heatern around the ball valve, the sauce was coming out boiling resulting in very short filled bottles. Using the Thermapen, the sauce was around 205F while the digital read out was saying 80C. 205F=96C, display read 80C. Waaaay off. For the next batch, I compensated. It will take a few batches to get it dialed in.

Learning curve was pretty steep. Next batch was Tropical Ghost Sauce which has bits of carrot. The bits are pretty small, but enough to get stuck in the barb every 3rd or 4th bottle. Stop, put a bowl under it, use a wire to unclog it, Big Mess!!! Sometimes the sauce would stop up, then splooge out, overfilling the bottles making a big mess on each bottle that then had to be wiped clean on the threads before capping.

Inside of the fitting at cleaning

Another note is, the whole thing is so high sitting on the table and hotel pans, I had to get a stepstool to be able to clean it. When finished with a batch, the jacket is still VERY hot. I was wanting to save the distilled water in the jacket for the next batch, so I didn't want to drain the water just to clean it. It took over 2 1/2 gallons of distilled water for the jacket.

I ended up filling the kettle with cold soapy water, which chilled the jacket enough to warm water to clean it soon after finished with filling.

And then had to drain the soapy water into a half gallon scoop and dump into a 5 gallon bin.

Good points...It is Heated! For the Tropical batch, the batch was large enough that I put half in the hopper and half on the stove. Both seemed to heat up at the same rate. Benefit of the Adgie...(agitator) was that I didnt have to babysit it stirring it like I did with the pot on the stove.

The ball valve was pretty good on the GhostFire, which is pretty homogenous. Accurate stopping. It did kind of have a little latent drip between bottles. I ended up not using the measuring cup prop. Just held them by hand. It did not go so well with the Tropical with the carrot bits.

The agitator was a great feature during processing, and the heating feature will be good once I get the read out correlated to the actual sauce temp.

2 thicker sauces coming up this weekend. BBQ and the new Spicy Catsup. Those will be using the larger barb. We'll see....

Last edited: