After running into "space" issues using a single mini greenhouse on a brewing heat pad this year I have decided to upgrade my setup for next season.

My options were to buy a second heat pad (for a second mini greenhouse) or buy a store seedling heatmat (to hold two mini greenhouses).

Ignoring options of buying something it's back to the DIY and this will be a short thread on my build.

The given dimension I worked with are the two mini greenhouses (Bunnings) due to being a good product at a good price.

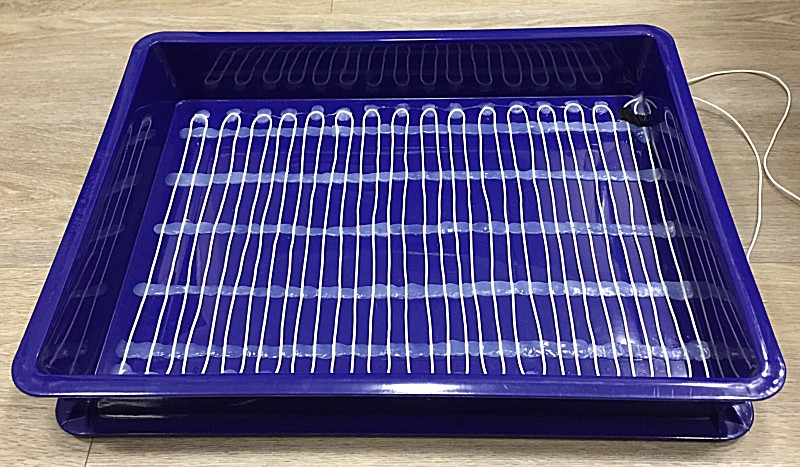

I found a sturdy plastic tray (with acceptable dimensions) at the local plastic shop and had some silicon resistance wire ordered some months back (0.6 Ohm/m)

Keeping things simple and using only electrical tape and clear silicone progress so far...

Did some testing and it comes out at a reasonable 8.8 Ohms. It will be powered by either a 12V or 19V adapter (still to decide) and this will give a final power output of 16W or 41W.

It houses the two greenhouses perfectly and I am now deciding on a thermal mass as a filler between the heating wire and the bottom of the mini greehouses. Any suggestions ???

Thanks for stopping by and update to follow.

My options were to buy a second heat pad (for a second mini greenhouse) or buy a store seedling heatmat (to hold two mini greenhouses).

Ignoring options of buying something it's back to the DIY and this will be a short thread on my build.

The given dimension I worked with are the two mini greenhouses (Bunnings) due to being a good product at a good price.

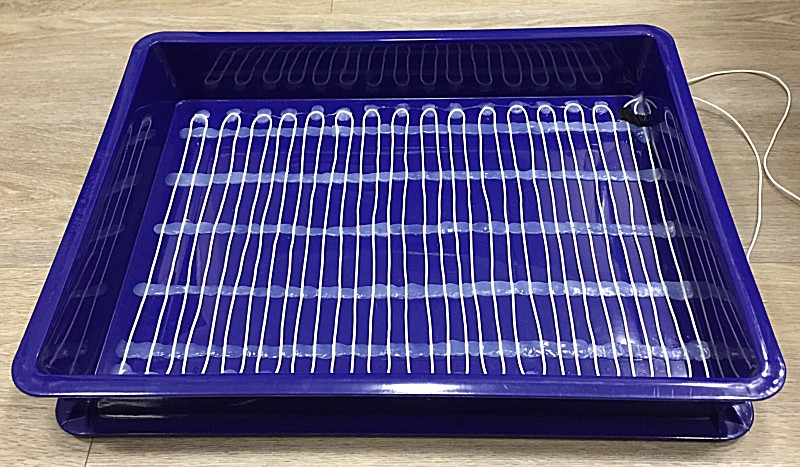

I found a sturdy plastic tray (with acceptable dimensions) at the local plastic shop and had some silicon resistance wire ordered some months back (0.6 Ohm/m)

Keeping things simple and using only electrical tape and clear silicone progress so far...

Did some testing and it comes out at a reasonable 8.8 Ohms. It will be powered by either a 12V or 19V adapter (still to decide) and this will give a final power output of 16W or 41W.

It houses the two greenhouses perfectly and I am now deciding on a thermal mass as a filler between the heating wire and the bottom of the mini greehouses. Any suggestions ???

Thanks for stopping by and update to follow.