The_NorthEast_ChileMan said:

I want to apologize if I seemed questioningly you on your posts. Having dealt with a few members from different parts of the world I wanted to make sure we are on the same page as obviously we don't have a language issue.

Another question, are you familiar with preserving in tin cans? As far as I know it's a much more complex procedure than using a jar with removable lid that just needs a hot bath to make it shelf stable. Fast forward to 03:30.......

EDIT: And I stumbled over this, , that might prove helpful!

And the young lady with the handle SalsaLady is our resident guru on all things done in a kitchen! Whatever she says is gospel around here...

No problem. We learn English from kindergarten in Pakistan. Also I did my undergrad from the United States, however that has no bearing on my English skills.

I don't believe that tin canning is much different from glass bottle canning, other than the fact that you require some specialized equipment for the double seaming process.

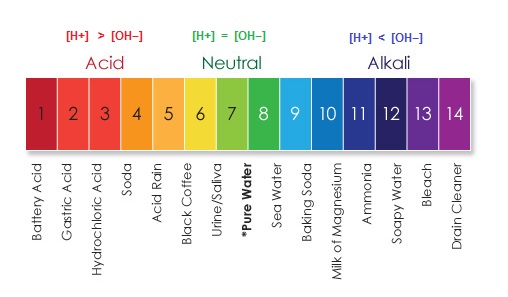

My confusion still stands as from what I have gathered we need to prevent any chances of our product being infected by clostridium botulinum, the bacterium that causes botulism. According to Cleveland Clinic:

"To

kill C botulinum spores, set your pressure cooker to 116°C. You need to cook foods until their internal temperature is 85°C for 10 minutes."

Now I have read in multiple places that for canning peppers contained in a low pH medium, you don't require pressure canning, rather you can just use regular water bath heating.

I am confused by the fact that gherkins / pickled products are also sold in plastic (PET) containers:

https://www.walmart.com/ip/Best-Maid-Dill-Pickles-1-gal-Plastic-Jar/10308508

How is this sterilized? I think if you heat sterlize plastics, there is a chance of phthalates and other nasty stuff leaching out into the product.

So in conclusion, I want to know whether it is safe to use UV (ultraviolet) sterilization rather than heat sterlization in addition to the following:

1. Is vacuum sealing necessary for commercial canning?

I believe not, since I don't think tin cans are vacuum sealed.

2. Is vacuum sealing done on tin cans also?

I don't think so

3. Is it necessary to treat the product with boiling water for sterilization? Is this done for both glass jars and tin cans?

Probably yes, unless we can use UV instead of heat sterilization

4. Is UV sterilization an adequate alternative to steam/boiling water sterilization?

Need to figure this out

5. Can we can peppers in plastic jars/pails? If yes, how is this product sterilized?

Yes, but still need to figure out how the product is sterilized for this case

6. How do you determine the expiry date?

Still need to figure out