solid7 said:

Nice work. Love seeing good old fashioned craftsmanship.

.

I've always wanted a high carbon steel kitchen knife. (a proper santoku) I'm thinking about making my own from an old bastard file. I am thinking to make the handles out of birdseye maple.

.

I need to go back and polish up my knowledge of metallurgy a little bit. Files seem to be really easy to get ahold of, but I'm also tempted to use a piece of D2 that I've got lying around. The only problem is, I'm not exactly sure how I'd work the D2. It's too thick, and I don't have a milling machine, anymore. Not sure if it's a good candidate for hot working, or not. (it's been years since I did any non-machining type metal working, other than welding)

Thanks, I'm the type that would rather make something than buy it. Real craftsmanship is becoming quite rare nowadays, so I take every opportunity to make something by hand instead of buying it.

My next few knives will be larger kitchen knives, a santoku is definitely on the cards.

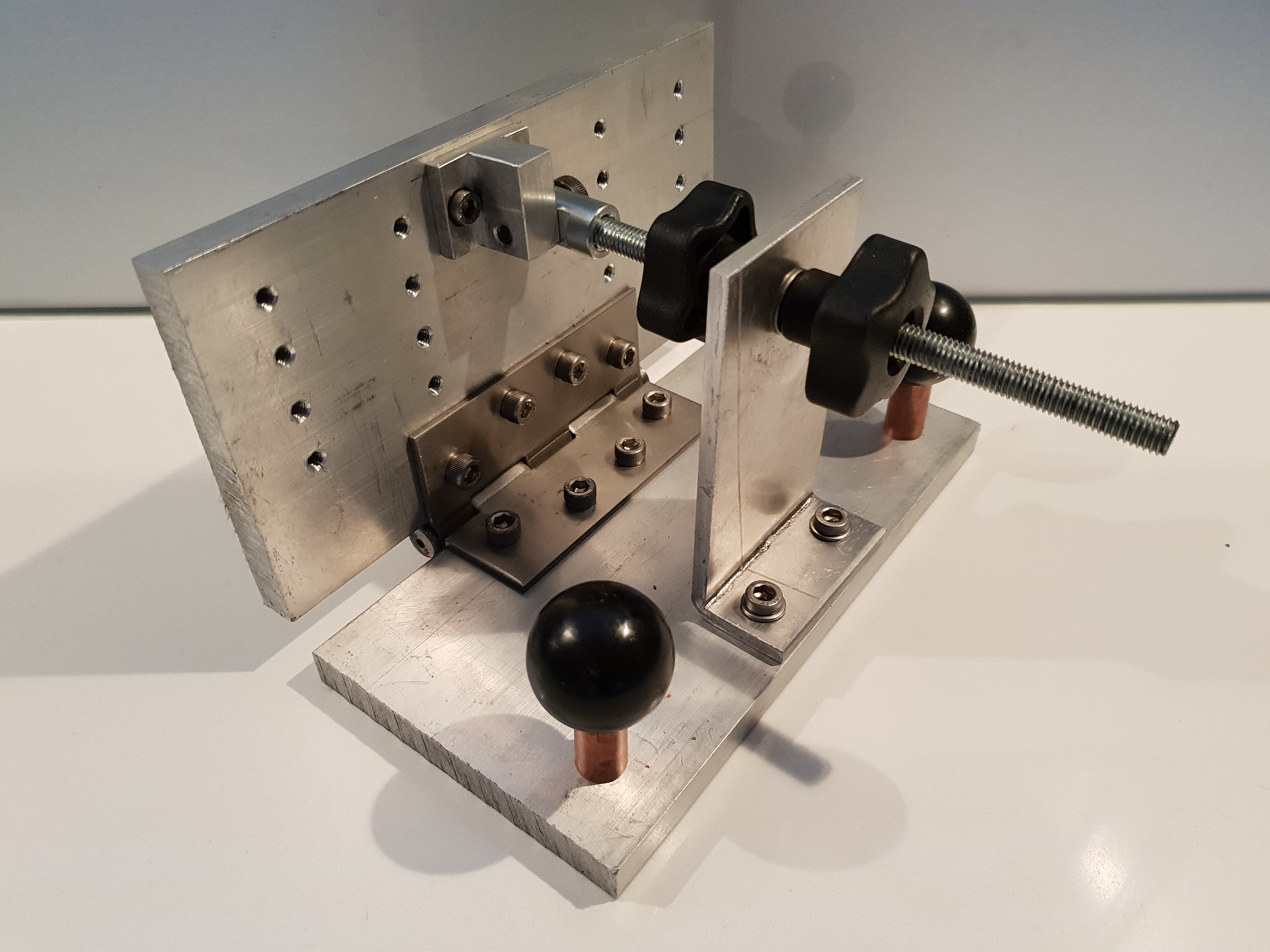

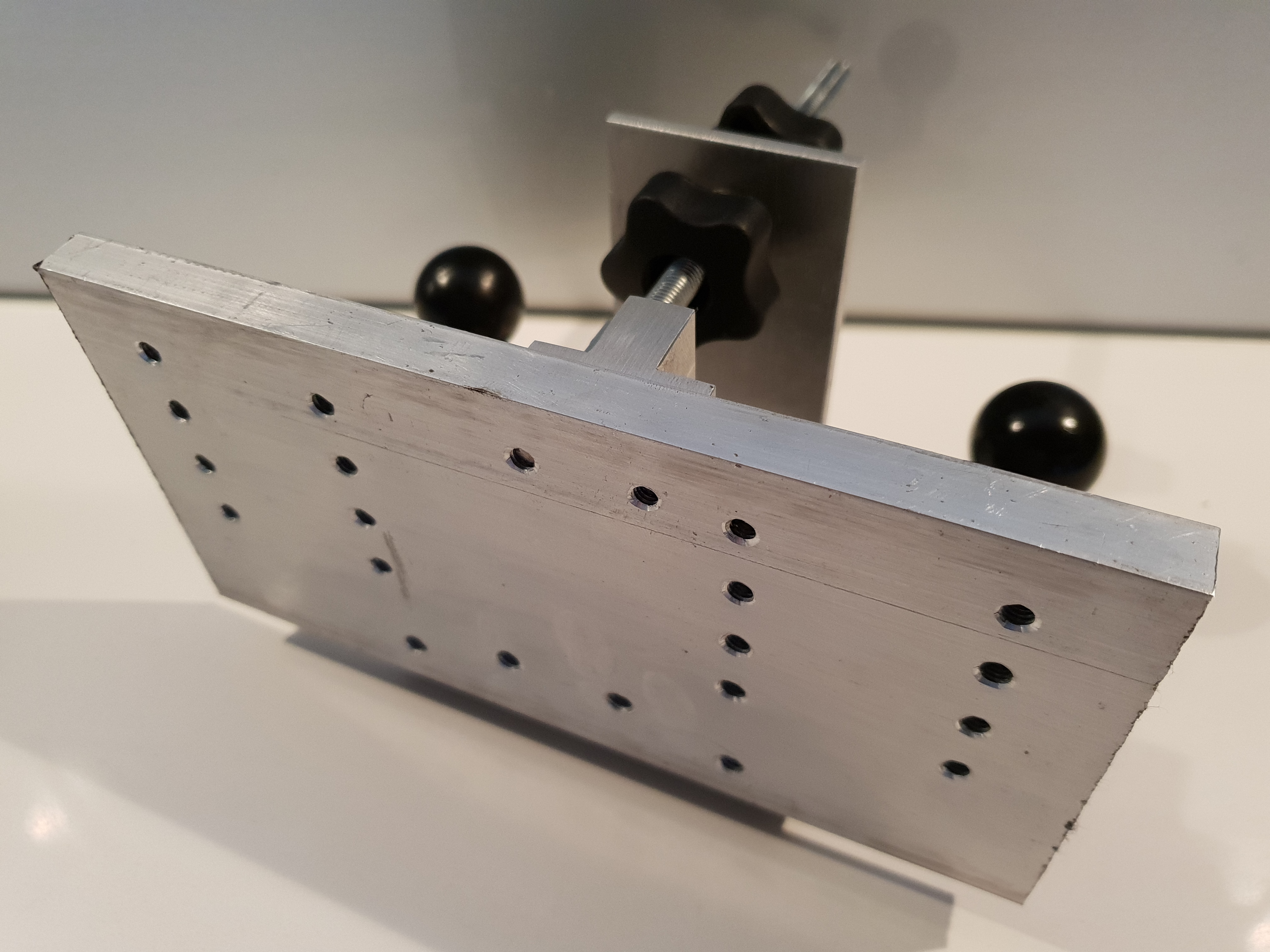

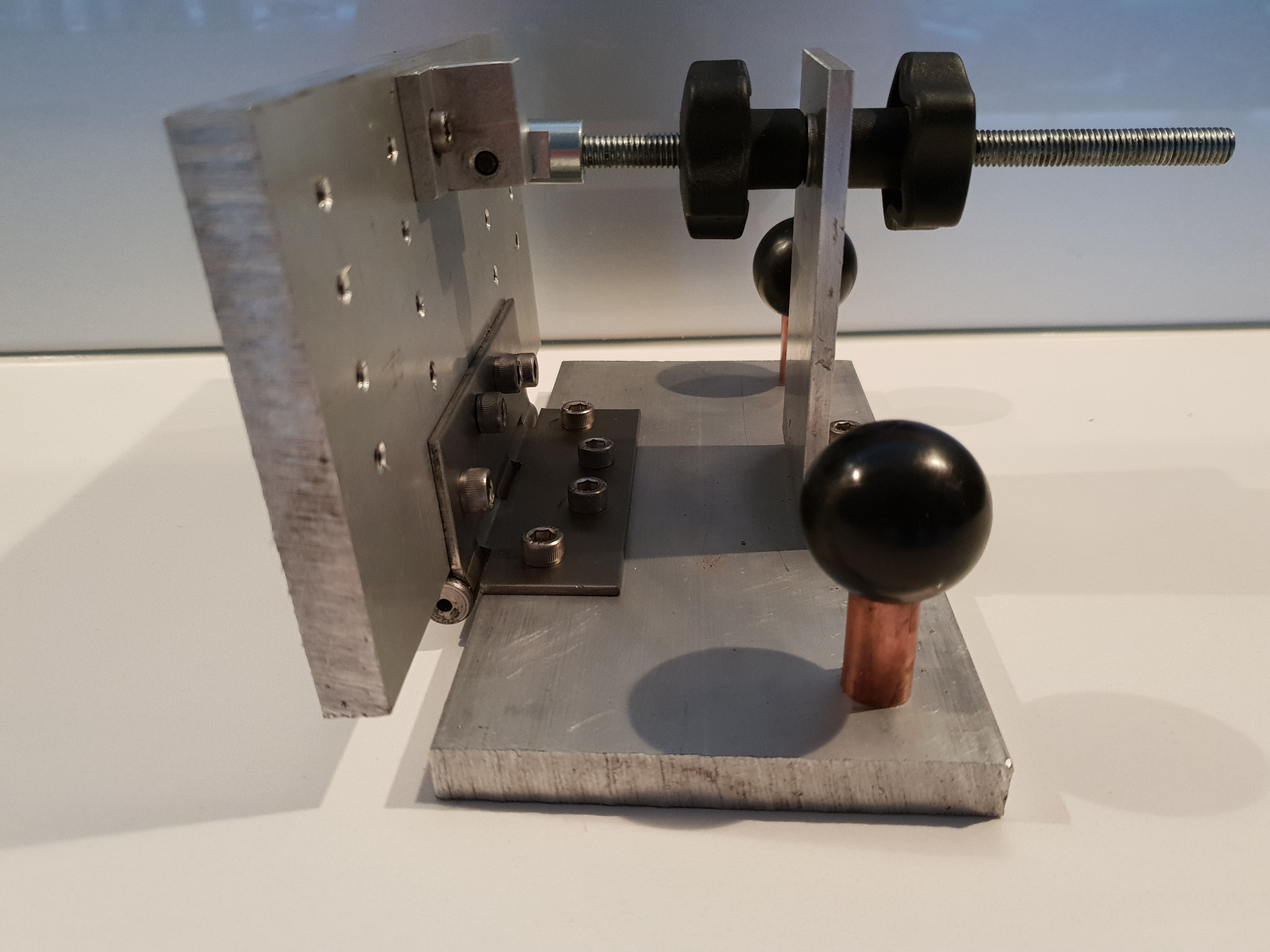

I made my own bevel grinding jig......

......to use on a vertical belt sander that I purchased new, then modified with a larger table to accommodate the jig.

This is how you grind the bevel.

A file would be great to use for a blade, they are made of ideal quality steel but may be a bit narrow for a Santoku unless you can find something reasonably wide. There would be no need to heat treat or temper as long as you keep it cool while grinding.

The D2 would also make for a great blade, as with the file, if it is already hardened there would be no need to heat treat or temper.

All in all, my first knife cost less than $0.50 to make, the only thing I purchased was the brass rod for the handle pins. The rest was destined for the bin. The biggest factor was time and the tooling required.

SR.