Thanks to lazy, I was able to start working on this again. He keeps saying I should build kits.. maybe.

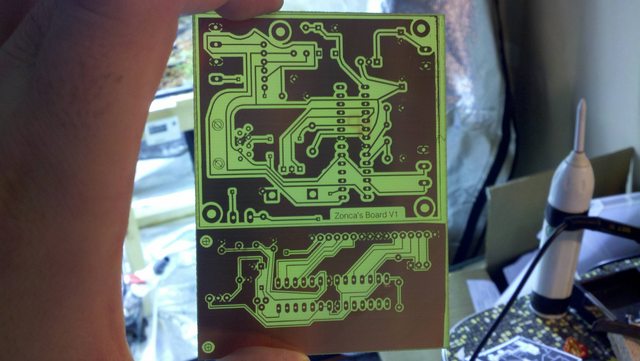

This is the prototype for the environmental controller portion, funded by lazy. It is setup to regulate temperature and RH in a grow tent. Far more switching power than what is needed (25A)

, but I tend to overbuild. Still plenty of digital pins for later expansion, only about 1/3 of the available program space is in use (It's mostly just for the menus). - Plenty of refinement to go..

I'm thinking I'll divide the functions I originally listed over a handful of modules that can control one another.

On a completely different note, does anybody know of any IT openings in the greater Montana area?

On the pH front, I'm thinking of using this

Atlas Scientific Stamp and setting up simple feedback loop. Instructing the microcontroller to power either of the dosing pumps for the PHup and PHdown solutions.

//// Something like this

int phup = 4;

int phdown = 5;

float PHreading;

float PHswing;

PHswing = .2;

loop

{

PHreading = ReadPH();

if((PHreading + PHswing) < desiredph )

{

digitalWrite(phup, HIGH);

delay(3000);

digitalWrite(phup, LOW);

}else{

digitalWrite(phdown, HIGH)

delay(3000);

digitalWrite(phdown, LOW);

}

}

, but I tend to overbuild. Still plenty of digital pins for later expansion, only about 1/3 of the available program space is in use (It's mostly just for the menus). - Plenty of refinement to go..

, but I tend to overbuild. Still plenty of digital pins for later expansion, only about 1/3 of the available program space is in use (It's mostly just for the menus). - Plenty of refinement to go..