-

Politics are not permitted. There's plenty of places to discuss that elsewhere, and a hot pepper forum is not the place. Thank you for respecting the community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

hobbies Shorerider's Workshop.

- Thread starter Shorerider

- Start date

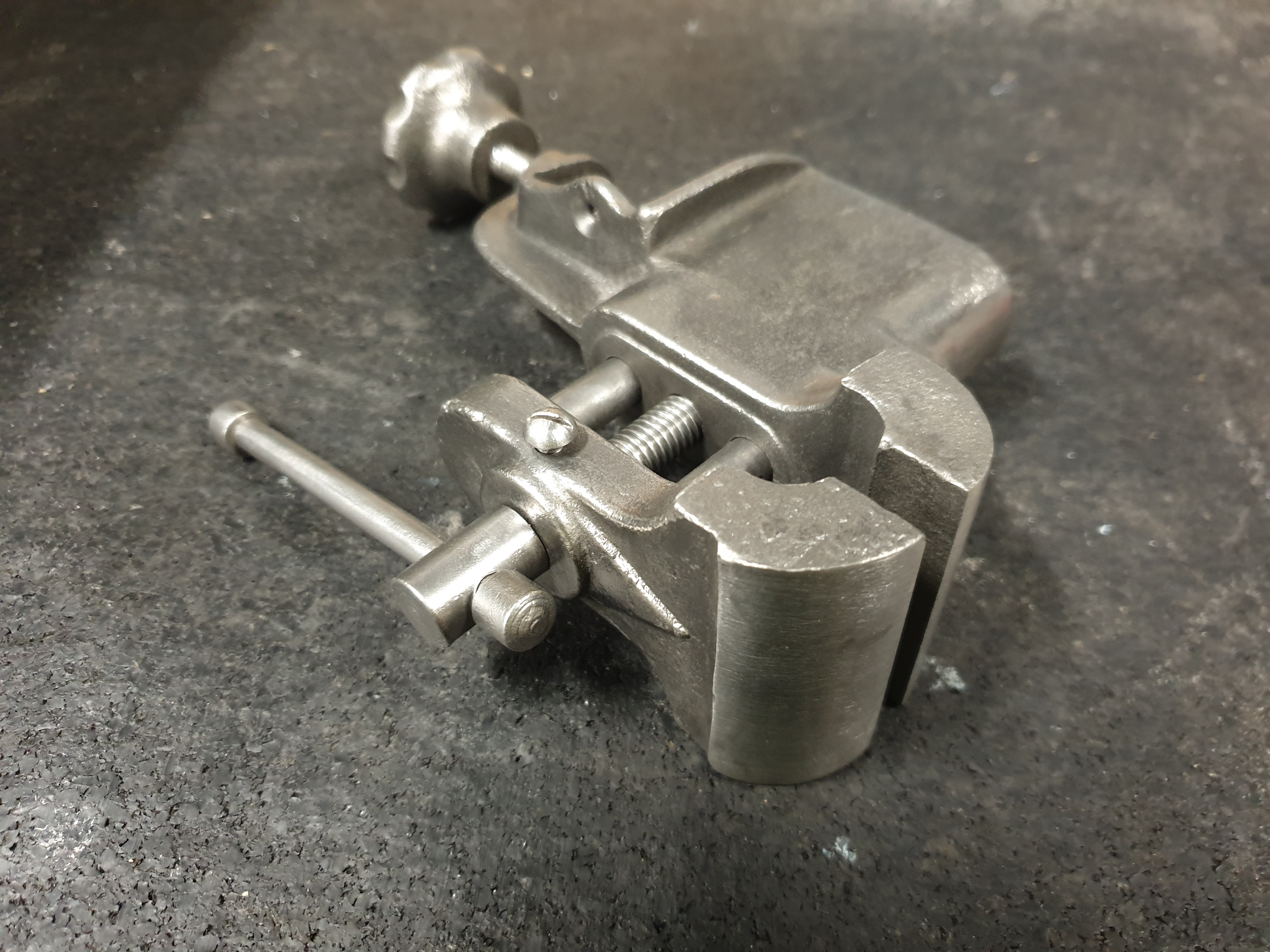

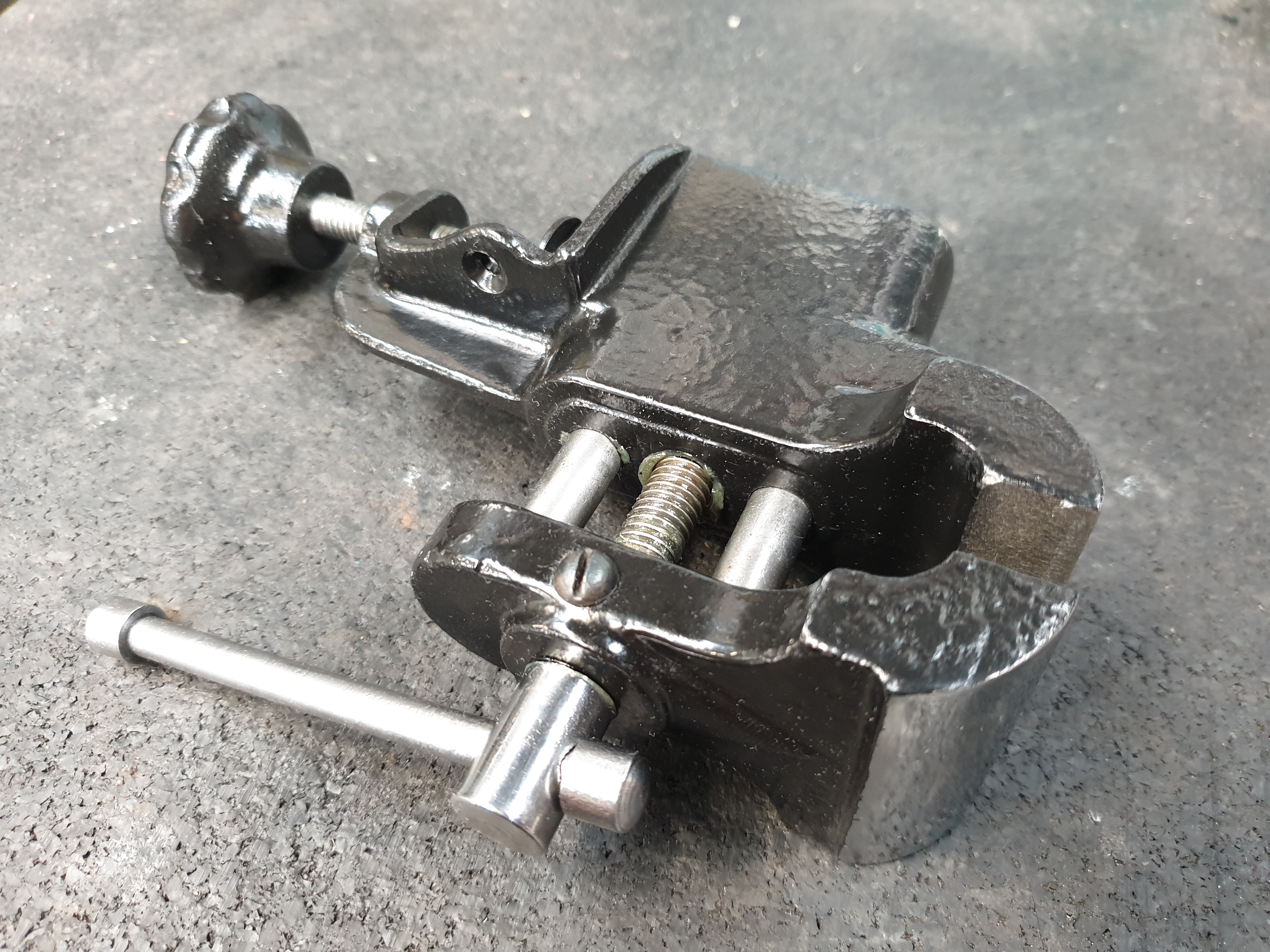

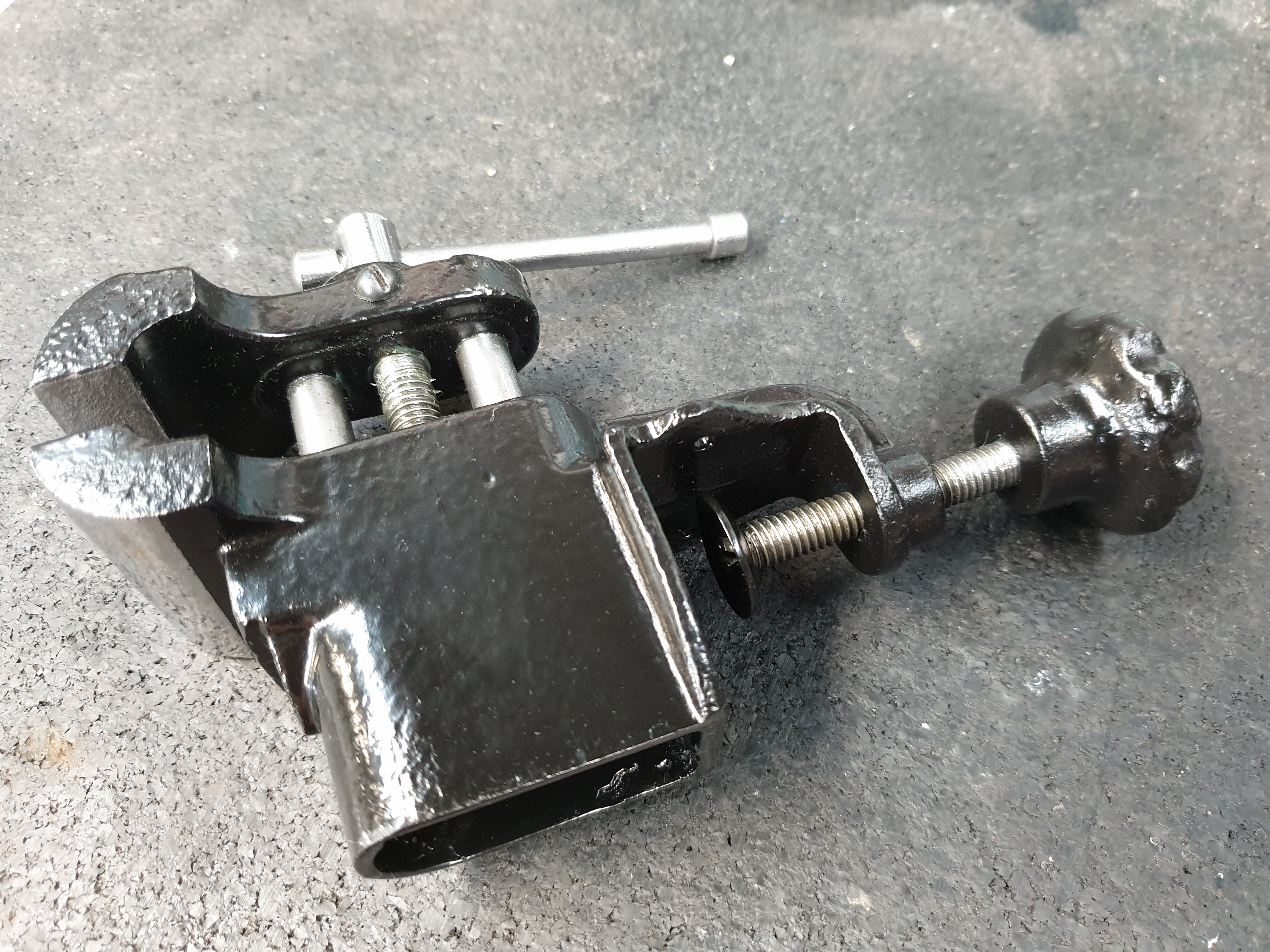

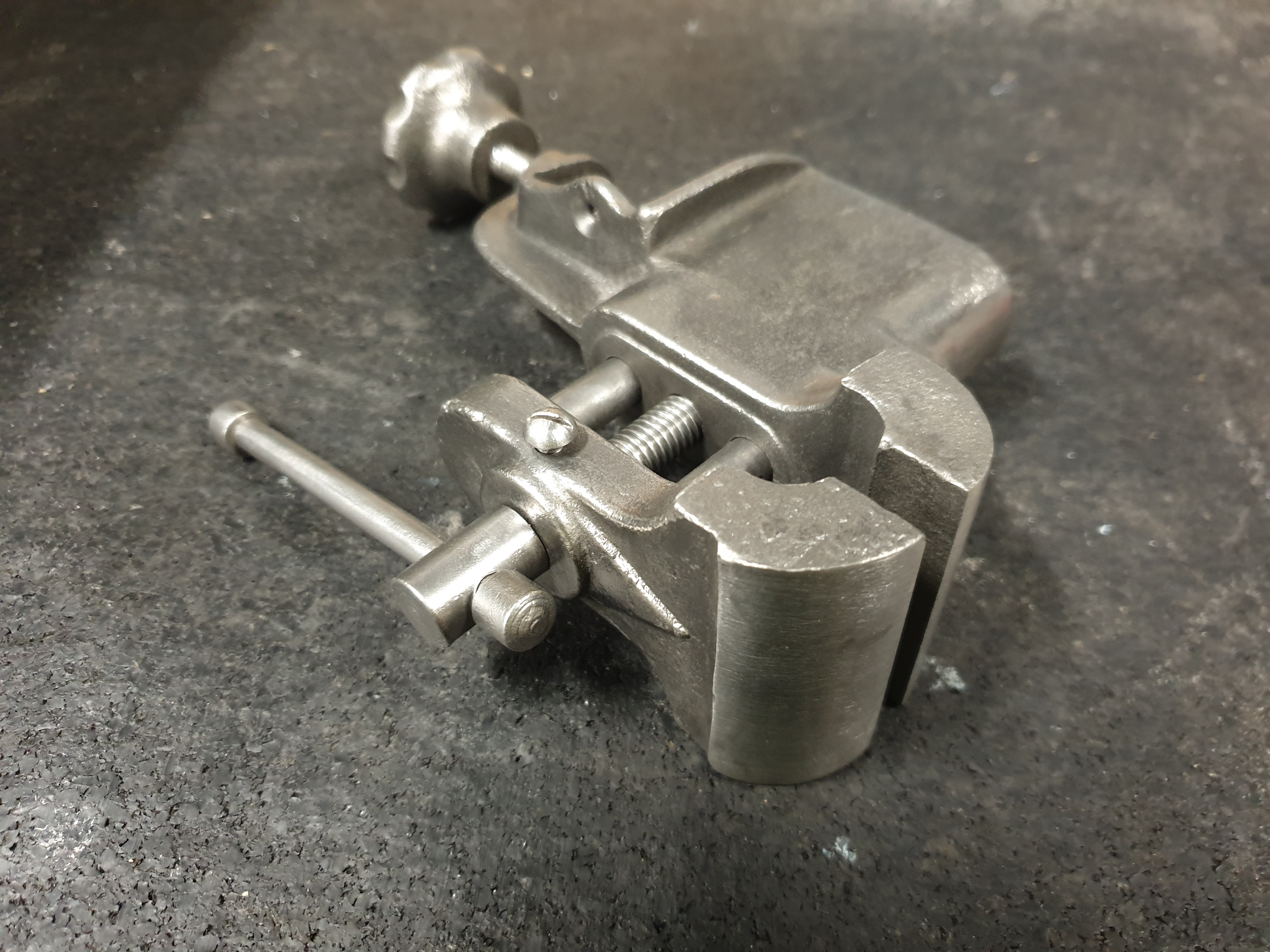

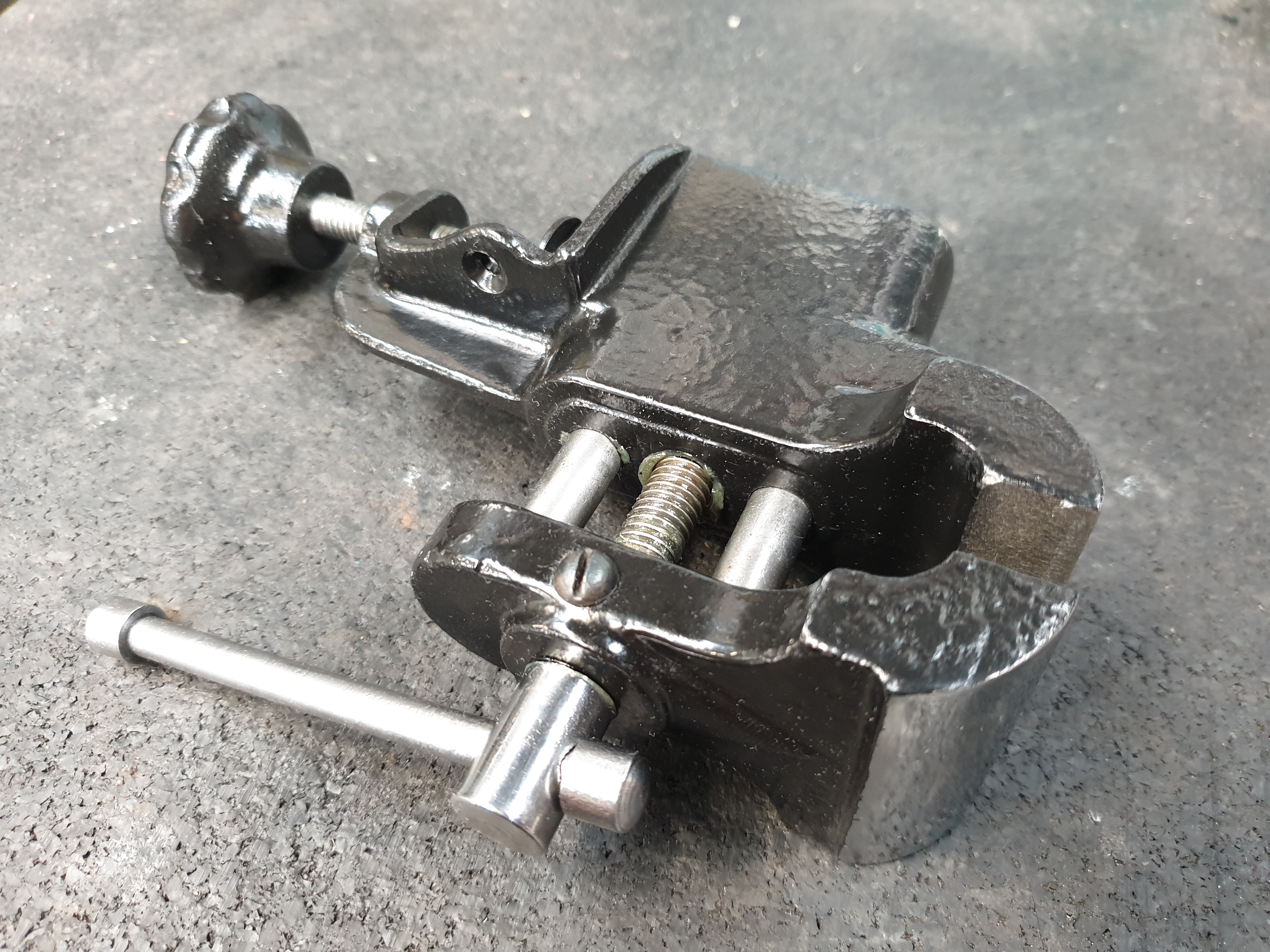

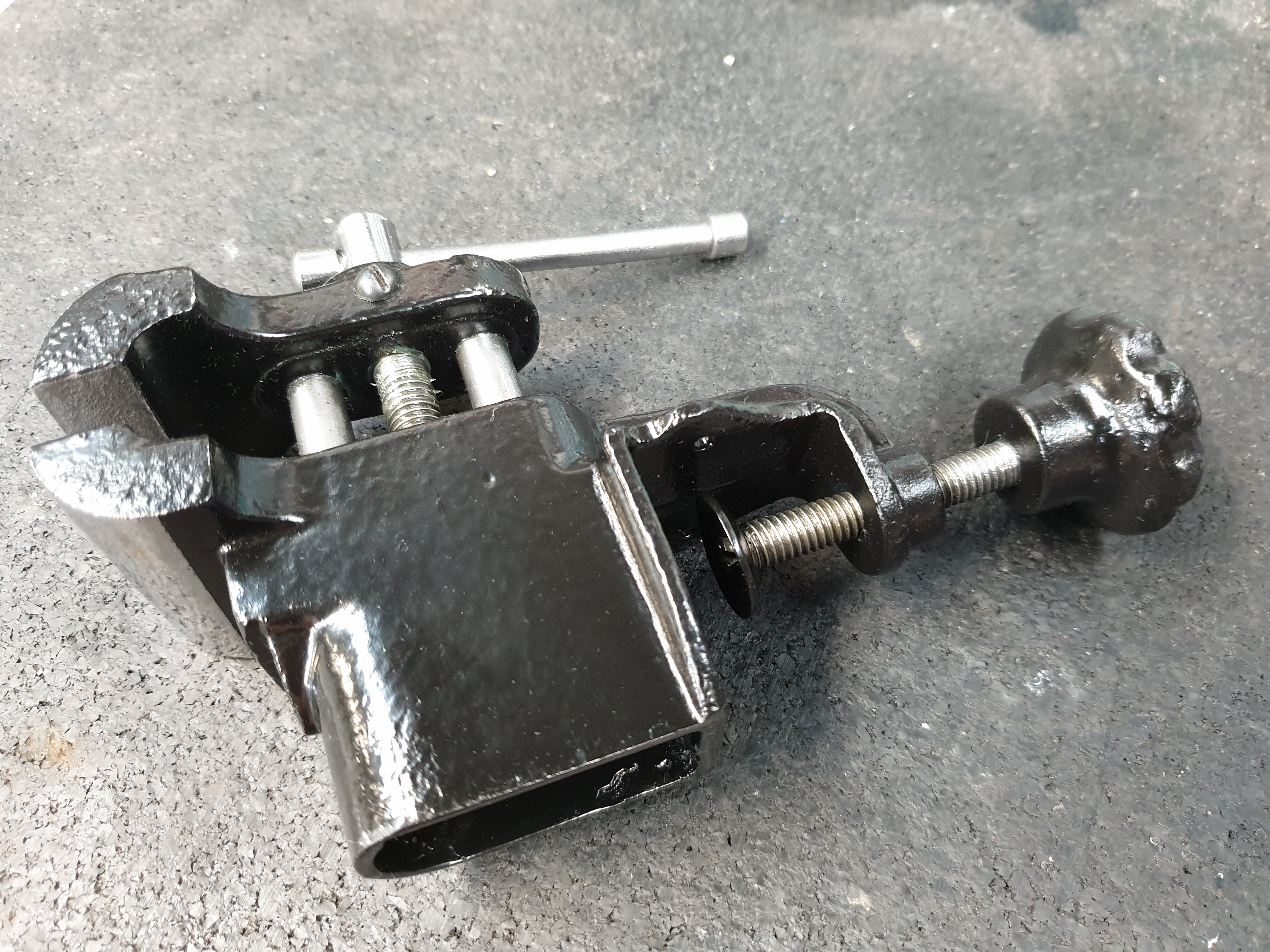

A while back I bought this jewelers vice at a swap meet, along with some other bits which included jewelers vice I restored previously.

This one had a chip taken out of it that needed to be repaired.

So, I busted out the welder, and after a bit of welding and grinding, I was reasonably happy (who am I kidding, I'm never happy.... ) with the outcome.

) with the outcome.

Then, I stripped it down and cleaned up all the rust.

I'm not one to smooth out casting marks from cast iron, I believe it detracts from the age of the piece. I found a minute remnant of black paint, so that's the color I chose to paint it.

Polished detail.

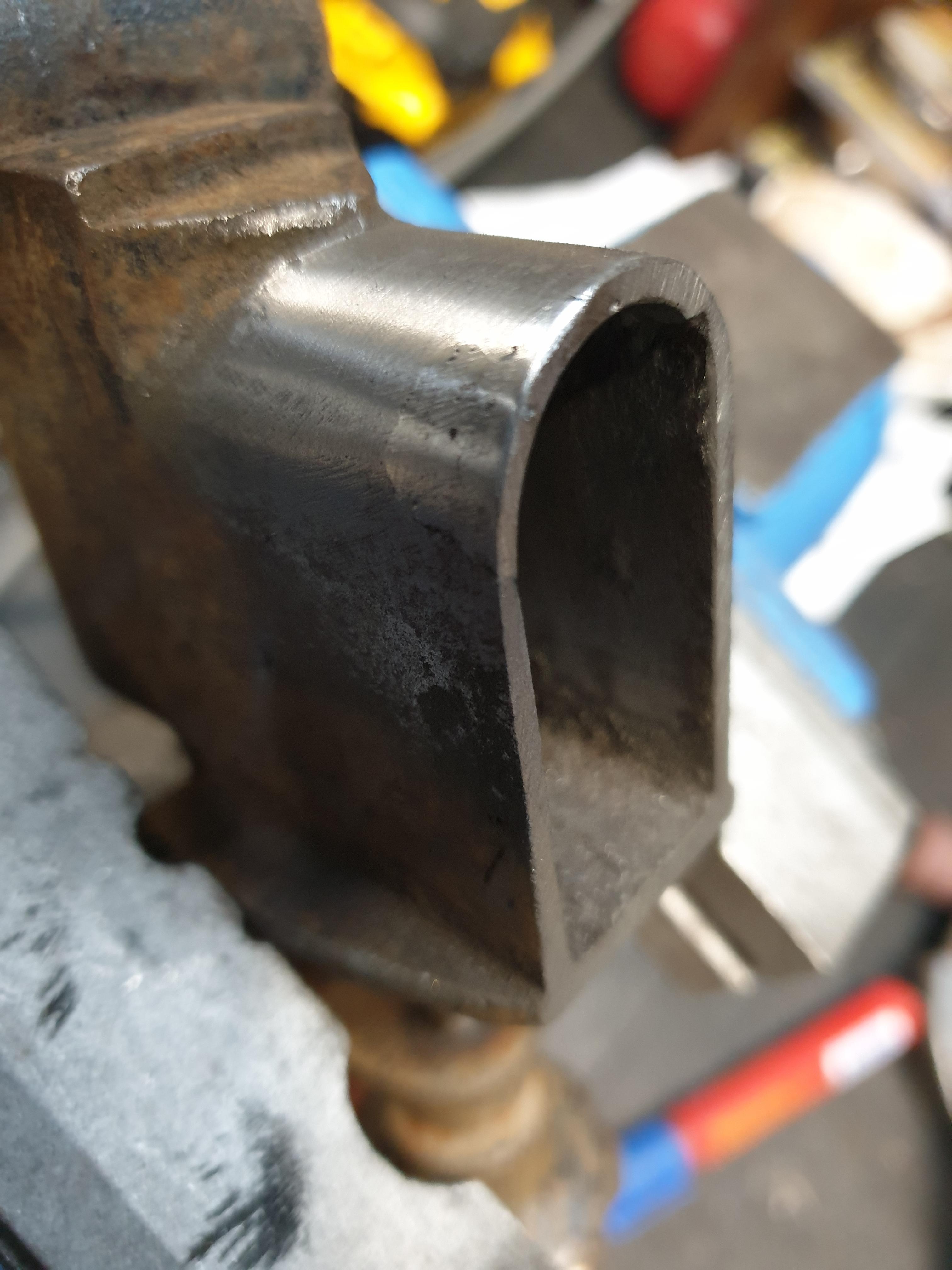

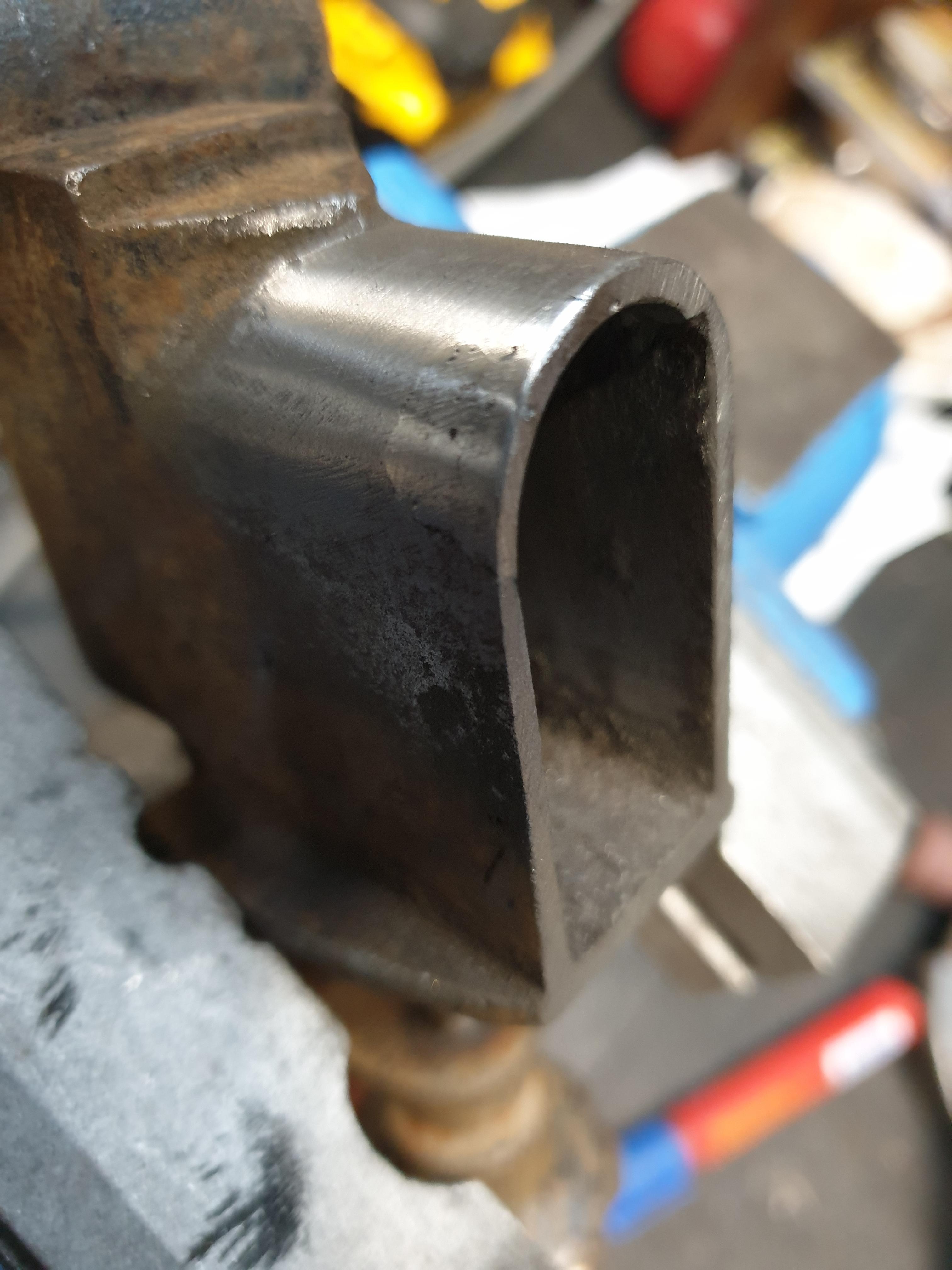

The repair.

SR.

This one had a chip taken out of it that needed to be repaired.

So, I busted out the welder, and after a bit of welding and grinding, I was reasonably happy (who am I kidding, I'm never happy....

) with the outcome.

) with the outcome.

Then, I stripped it down and cleaned up all the rust.

I'm not one to smooth out casting marks from cast iron, I believe it detracts from the age of the piece. I found a minute remnant of black paint, so that's the color I chose to paint it.

Polished detail.

The repair.

SR.

Thanks, unfortunately I am no jeweler............yet.nmlarson said:WOW! That is stunning! You're a master. But, I'm still waiting to see the jewelry.

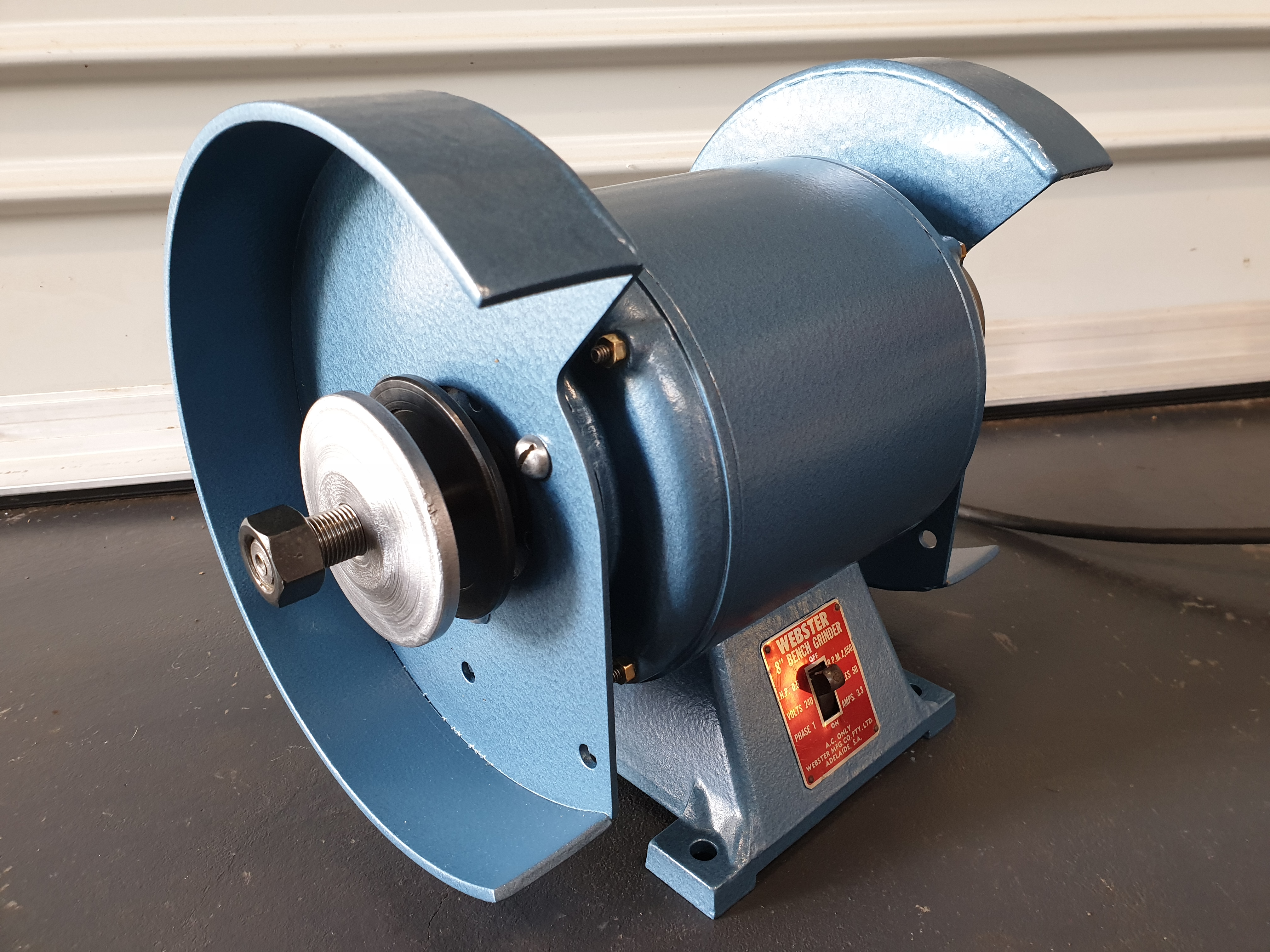

I used a gasless MIG welder. I've only used it a handful of times so far but am really liking it. Here's a weld on a bench grinder pedestal I've been working on.Ashen said:Smaw or gmaw on that repair weld?

Either way good job, CI is a bitch to weld properly

Yes, CI is a PITA to try and weld. I had to dial the power way down so I wouldn't melt the surrounding area. Luckily the repair was purely cosmetic, if it was in a stressed area, I couldn't see it lasting.

SR.

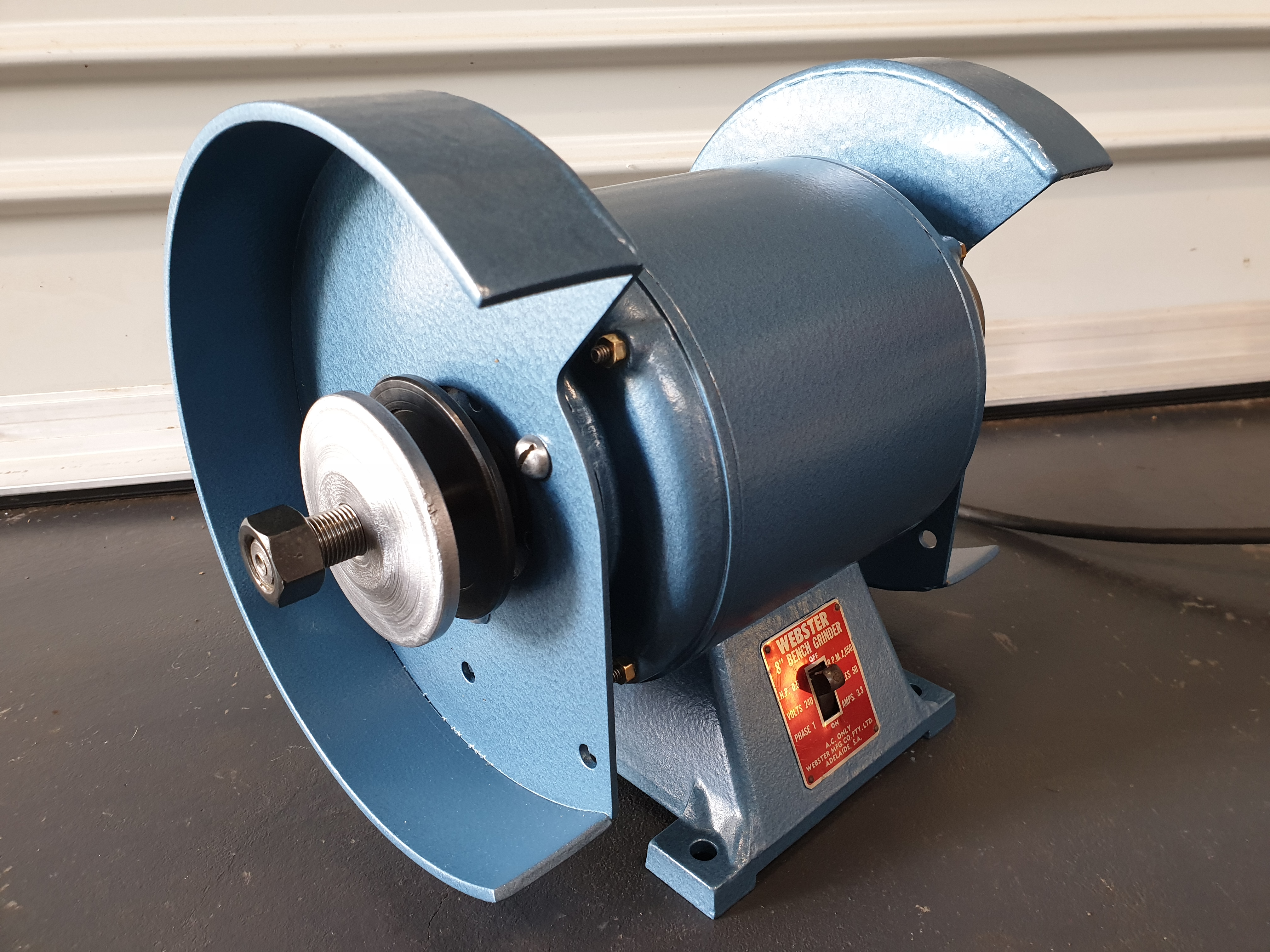

I've had this 8" bench grinder for a while now, it works great. But me being me, I wasn't going to let it continue to look the way it did.

Although the rust looks superficial, it was the hardest to remove rust I've ever encountered. I ended up using a paint and rust remover disc on my 6" grinder.

Brass nuts tell it's age, no one would use these nowadays. And yes, if there is brass, it must be polished

..

I also have a 6" bench grinder which is now mounted beside this one. Why two? So I can have grinding, polishing, buffing and wire wheels mounted full time.

Bonus restoration: Vintage internal spring calipers.

Before.

Cleaned.

After. I re-blued to achieve a factory look.

SR.

Although the rust looks superficial, it was the hardest to remove rust I've ever encountered. I ended up using a paint and rust remover disc on my 6" grinder.

Brass nuts tell it's age, no one would use these nowadays. And yes, if there is brass, it must be polished

..

I also have a 6" bench grinder which is now mounted beside this one. Why two? So I can have grinding, polishing, buffing and wire wheels mounted full time.

Bonus restoration: Vintage internal spring calipers.

Before.

Cleaned.

After. I re-blued to achieve a factory look.

SR.

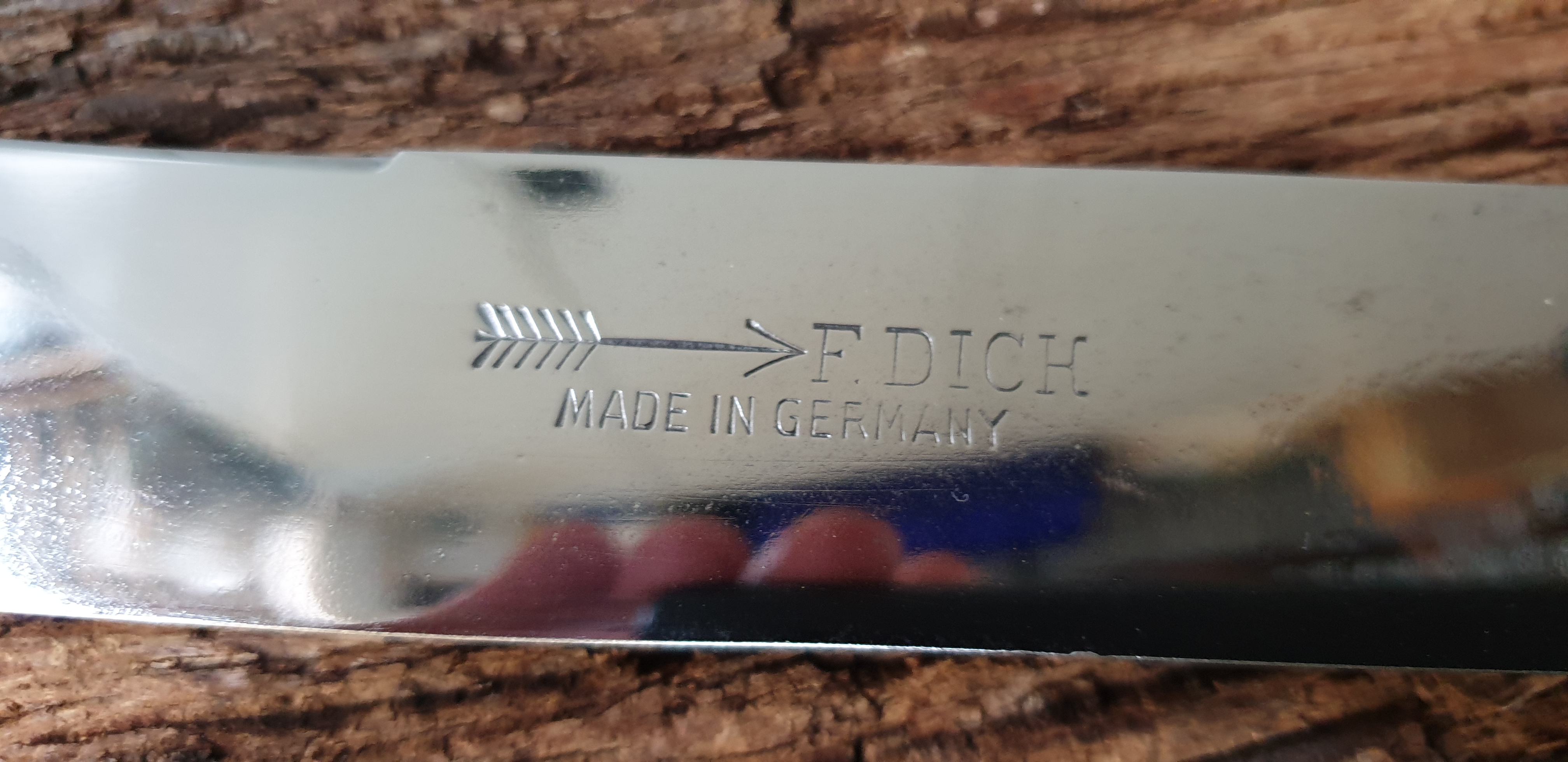

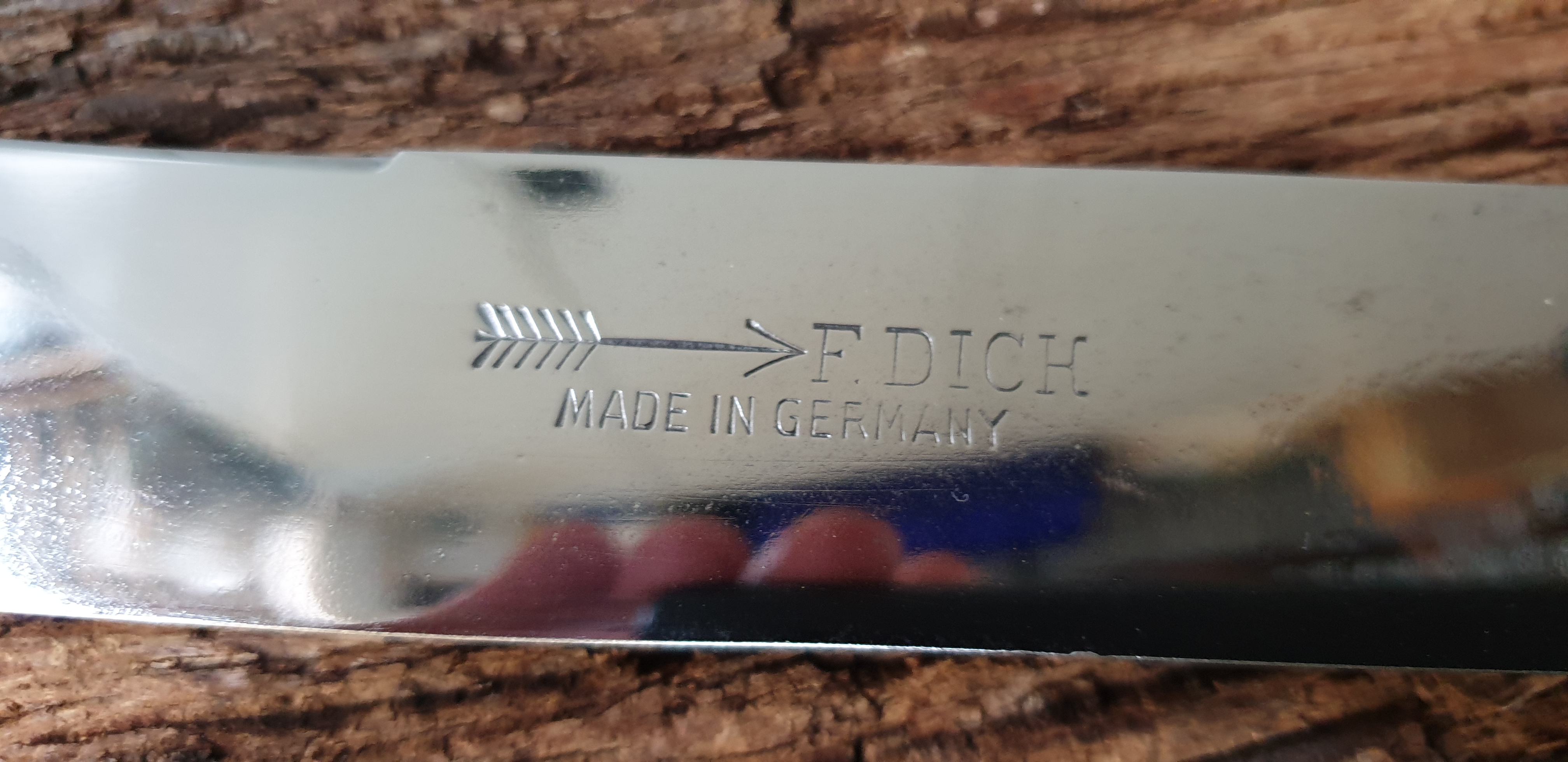

I picked up this vintage FDICK butcher's knife from a swap meet for a measly $10.

Bonus bike I saw which I thought looked very cool.

I haven't been able to find much information on the knife anywhere online, but it is reasonably old from what I can tell. One thing that I'm still a little curious about is the "K" in the logo. On the vintage FDICK sharpening steel I own, and anywhere else online, the K is more pronounced, and less like a H.

It should restore nicely at any rate, stay tuned......

Bonus bike I saw which I thought looked very cool.

I haven't been able to find much information on the knife anywhere online, but it is reasonably old from what I can tell. One thing that I'm still a little curious about is the "K" in the logo. On the vintage FDICK sharpening steel I own, and anywhere else online, the K is more pronounced, and less like a H.

It should restore nicely at any rate, stay tuned......

But you didn't pinstripe the grinder shame on you!

Good stuff!

Good stuff!

Here is the end result of many, many hours of work. I honestly didn't realise how much work it would take to get the blade to this stage, needless to say I am rather pleased with how it turned out.

The color of the handle was a real surprise, it's a dark chocolate color. As it is in the pics, it has only been sanded and no oil or varnish of any kind has been applied. It feels so nice to hold as it is, I think I may only apply a thin coating of Tung oil to it.

The color of the handle was a real surprise, it's a dark chocolate color. As it is in the pics, it has only been sanded and no oil or varnish of any kind has been applied. It feels so nice to hold as it is, I think I may only apply a thin coating of Tung oil to it.

Ashen said:That is a beautiful breaker. You are all set to butcher some meat now.

I wonder how it would look green?

I was doing some Googling obviously.

Now I am curious , what did you do to it to turn it green?

What do you mean by "Green"?

Ah ok, that was just poor lighting.

STALKER!

Skill Set:

Stalker

Color Blind

Stalker

Color Blind

Was tempted to make a JayT / "70's porn" lighting reference but I restrained mysel....... oh, never mind.