I know when small wineries make wine, they have a machine that corks the bottle with a pull handle, or automated 1-at-a-time machine. And then you take the bottle and put a plastic/foil type cap over it all and rest it on a 45 degree rack and push the bottle up into a round hole that causes that cap to shrink around the neck, etc...

Woozy bottles can be ordered with shrink bands. They say you can use a heat gun or hair dryer, which works... but not really smoothly. If you start directly above the bottle and then work the side and bottle while spinning it, you get the best shrink... but I'm sure there's got to be a better way.

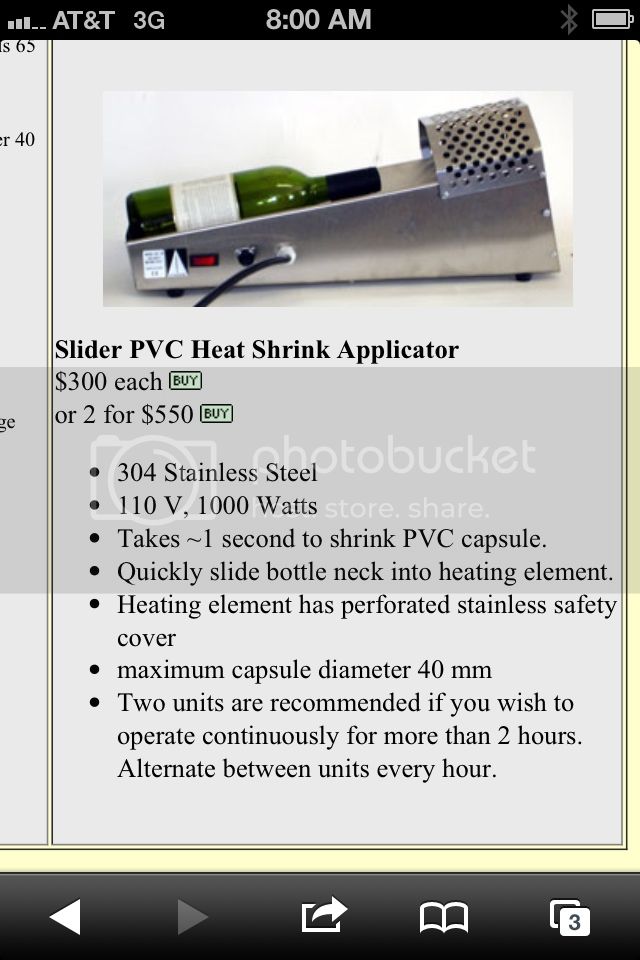

Perhaps a shrink banding machine much like the winery has? I tried looking online and at food service catalogs. They all start at 7500 and go to 20,000. I'm not a factory, but I also don't want to do 500 bottles with a heat gun. Inconsistencies, human error, etc. I want a uniform shrink.

Anyone know of a brand of 1-at-a-time heat shrink applicators that can be bought for under $250?

Woozy bottles can be ordered with shrink bands. They say you can use a heat gun or hair dryer, which works... but not really smoothly. If you start directly above the bottle and then work the side and bottle while spinning it, you get the best shrink... but I'm sure there's got to be a better way.

Perhaps a shrink banding machine much like the winery has? I tried looking online and at food service catalogs. They all start at 7500 and go to 20,000. I'm not a factory, but I also don't want to do 500 bottles with a heat gun. Inconsistencies, human error, etc. I want a uniform shrink.

Anyone know of a brand of 1-at-a-time heat shrink applicators that can be bought for under $250?